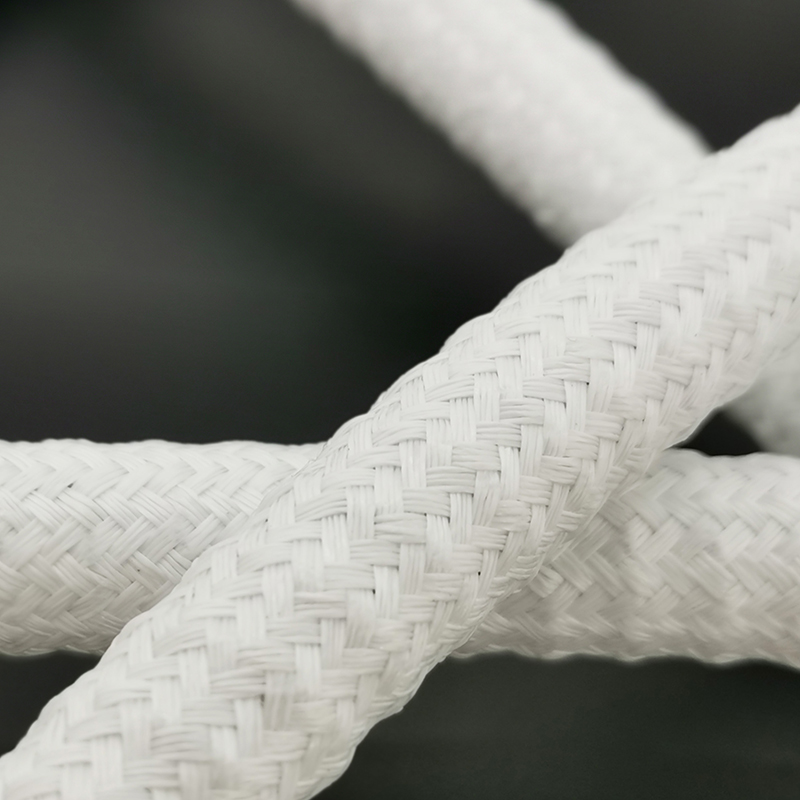

With the rapid development of modern electronic information technology, the problem of magnetic leakage and impact has become increasingly prominent. Tinned Copper braided sleeve mainly has the functions of mechanical protection and interference signal shielding. The Tinned Copper Braided Sleeve is laid with the surface of cables and wires. Shielding maintenance to prevent magnetic leakage and impact is also an important maintenance method to prevent nuclear magnetic resonance suppression from causing paralysis of the communication system in future wars. There are many other requirements for Tinned Copper Braided Sleeve for different uses, such as; they can be welded Performance, heat resistance, corrosion resistance, avoidance of air oxidation, electrical conductivity, flame retardant Tinned Copper Braided Sleeve, excellent shielding performance, light weight, low cost and other issues.

In response to this problem, there are many Tinned Copper Braided Sleeve manufacturers that specify the industry and corresponding performance requirements for Tinned Copper Braided Sleeve, ranging from raw material selection, braiding equipment maintenance, and wire tension sensors during the weaving process. Indispensable for people, we have developed a new type of Tinned Copper Braided Sleeve that is lighter in weight, has good softness, good heat resistance, high strength and high braiding density, and can meet the requirements of different uses.

There are currently two types of high-speed knitting equipment in China. One is the drop-spindle weaving method. The drop-spindle structure is more complicated, and oil stains on each part can easily pollute the product. The advantage is that the weaving speed is faster, but the quality is high. The rate is lower; the other is the flying goose style weaving method. Each part is distributed under the spindle to prevent kitchen fumes from being polluted. The speed is almost the same as vertical weaving. Nowadays, the knitting machines developed by China itself can basically reach production and manufacturing.

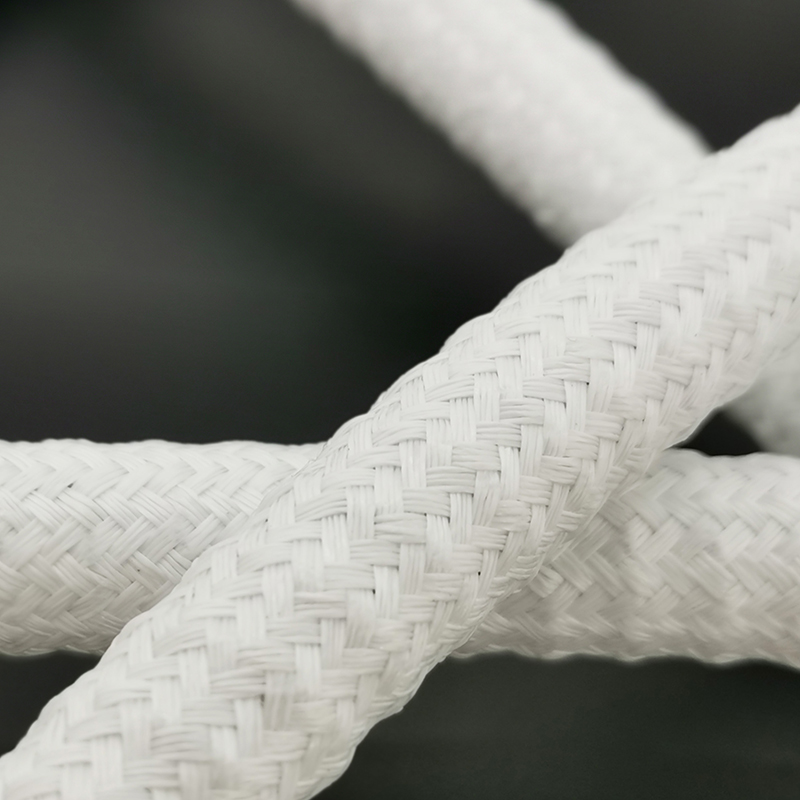

The raw materials are selected in order to better achieve the anti-electromagnetic leakage or anti-interference effect of the Tinned Copper Braided Sleeve, and at the same time achieve the weldability, flexibility, light weight, avoid oxidation, heat resistance and high toughness. and other performance indicators, Huiyunhai High-tech uses four raw materials: tinned copper wire, nickel-plated copper wire, tin-plated alloy copper wire and tin-plated copper-clad steel wire, and determines that the corresponding wire diameters are 0.1mm each. , two specifications of 0.12mm. Compared with past processing techniques, the wire is thinner.

The reduction of the wire diameter during the development process has put forward better requirements for the weaving process. Since the wire material is too thin, it is easy to cause wire breakage during the weaving process. The doubling reel was changed to a winding reel, and the doubled wire was selected. The special single twister is used for laying out the wire. At the same time, the tooling fixture of the doubling machine is changed to one that can install 48-spindle wire tubes, the doubling stroke arrangement is adjusted, and the doubling pitch is adjusted again. This method can make the doubling support The force is balanced and consistent, and there is no wire pressing.

Properly adjust the take-up brake pad according to the production speed of the Tinned Copper Braided Sleeve to keep the take-up speed consistent with the pitch gear speed. In order to better ensure that the new Tinned Copper Braided Sleeve is more conducive to cable threading, the brake pad friction is reduced at the take-up rotating transmission gear to minimize the take-up support force and ensure that the take-up support force is small. It is not easy to tear the product, which is beneficial to the high wire breakage rate during the weaving process, resulting in unnecessary waste. The new Tinned Copper Braided Sleeve after weaving with this method is hollow and will not be flattened after the wire arrangement. Flat shape, very useful for threading cables and wires.