Analysis of Bonding Problems between Automotive Wiring Harness Protection Sleeve and Metal

July 17, 2023

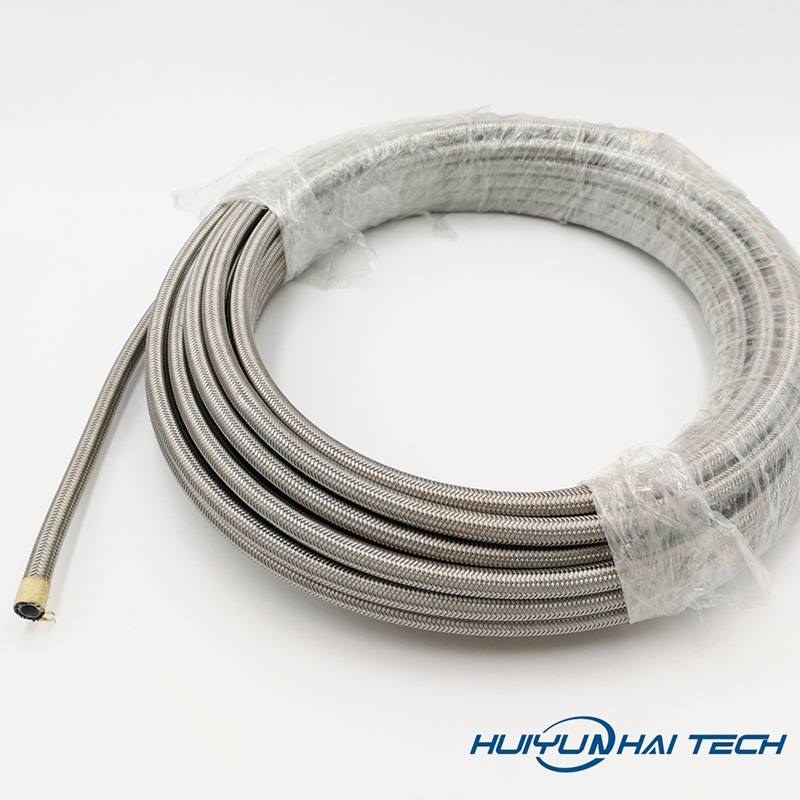

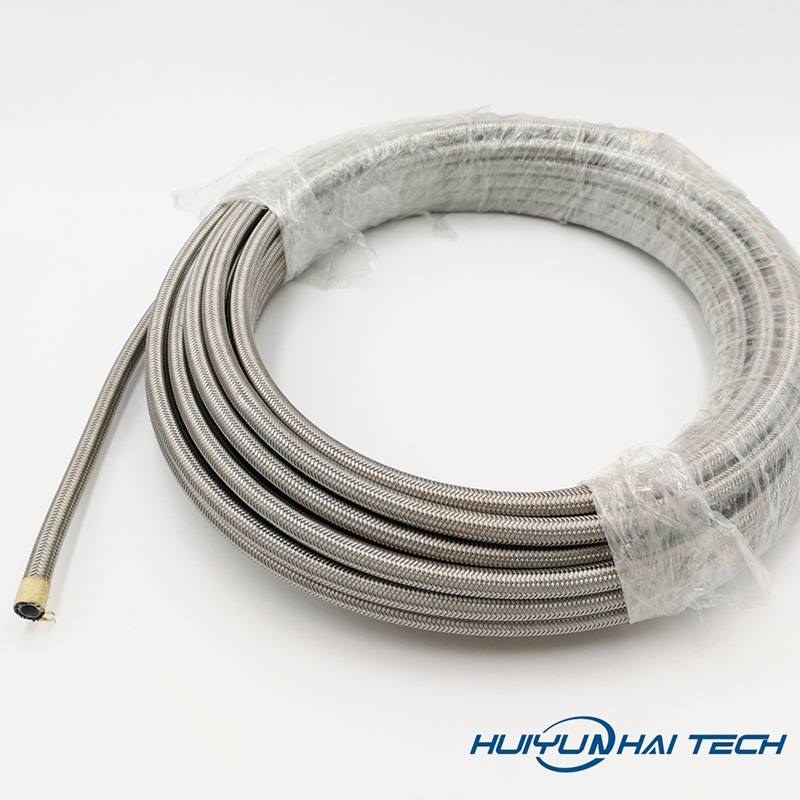

The protective sleeve of the Automotive Wiring Harness Protection Sleeve is made of natural rubber, while the metal frame is made of iron. The surface of the Cable Sleeve is sandblasted and cleaned with solvent gasoline, and then coated with an adhesive. How to solve the damage between the Cable Sleeve and the adhesive surface.

The adhesive you use is not special for natural rubber and iron. You can try other adhesives. There are many types of adhesives. Search for information on the Internet. When the metal vulcanizes, the pressure is insufficient. Is there oil spraying out of the formula? The spraying out of the compounding agent will also affect the bonding. High temperature vulcanization will also have an adverse effect on the bonding. The increase in the amount of S is beneficial to the bonding. After brushing, the surface glue was not dried enough, because it was recently discovered that the degumming indicated that the bond was still good before, indicating that the grade of the surface glue selected was matched with the Cable Sleeve. Another possible reason is whether the surface glue is fully stirred evenly before using, and there is precipitation in the Cable Sleeve, especially oil precipitation.

In the non-sticky place, the temperature is not enough, the adhesive is not enough for vulcanization temperature, the middle temperature is because the thickness transfer is slow, the temperature is low, the adhesive is not enough for vulcanization temperature, so it is not sticky. I have tried increasing and decreasing the vulcanization temperature, and the effect of increasing the temperature seems to be worse. It doesn`t matter if the time of the car wiring harness protective cover is shortened, or the adhesive is polluted by oil stains after brushing. You can make a nail iron to verify the adhesion. If it can reach more than 8, then look for problems in the product process. The amount of fillers and plasticizers has a certain impact on the protective sleeve of the Automotive Wiring Harness Protection Sleeve. In wet weather, it is best to clean the metal and dry it in an oven before applying glue.

How about the thinner used, whether the paint is stirred evenly when using the paint, if it is not uniform, it will also lead to uneven surface quality. When using metal materials, whether there is oil pollution in the production or storage environment, if there is oil pollution, it will greatly affect the vulcanization bonding effect. You have to check from the Cable Sleeve of the Automotive Wiring Harness Protection Sleeve you are using to see if there is any pollution, such as dust, oil, etc. The pollution of the Cable Sleeve will also affect the bonding quality.