The chemical composition of the failed Tinned Copper braided sleeve was analyzed, and the microstructure and fracture morphology of the failed Tinned Copper Braided Sleeve were observed by metallographic microscope and scanning electron microscope. The results show that: because the failed tin-plated copper Braided Sleeve material belongs to the "pseudo-200 series" austenitic stainless steel, its Mn content is high and Cr content is low, which cannot achieve the corrosion resistance that stainless steel should have, and its rust and cracking are corrosion failures .

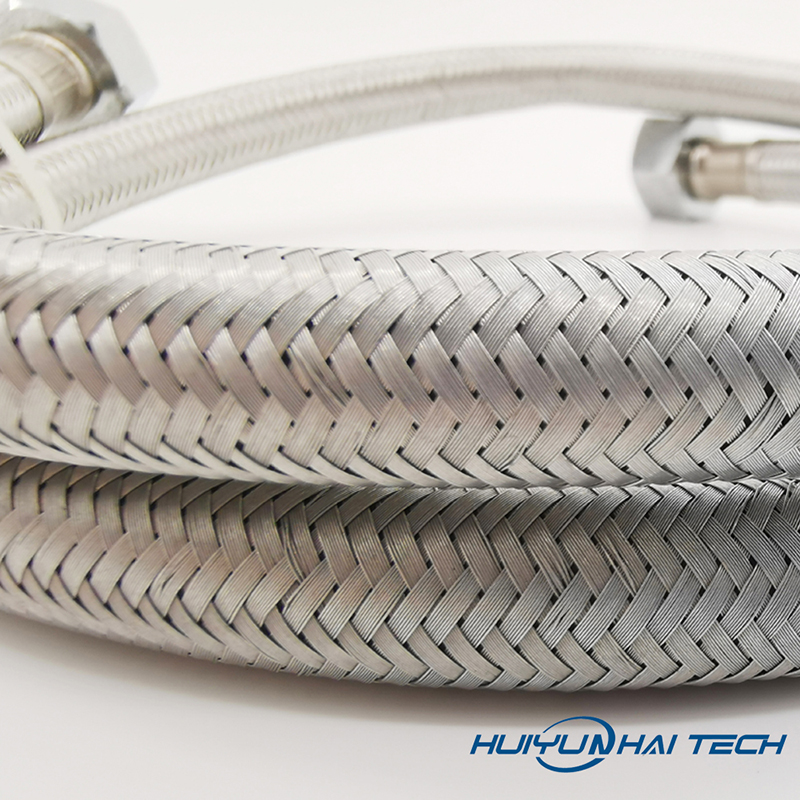

1. Tinned Copper Braided Sleeve is installed in the liquid conveying system as a flexible pressure-resistant pipe fitting to compensate for the mutual displacement of the connecting ends of the pipe or machine or equipment, absorb vibration energy, and can play the role of vibration reduction and noise reduction. Good flexibility, light weight, corrosion resistance, fatigue resistance, high and low temperature resistance and many other characteristics. The austenitic tin-plated copper braided casing installed in the water source transmission system of some households in a residential area has been rusted, cracked and leaked during use. In this paper, through the chemical composition analysis of this batch of tin-plated copper braided sleeves, the observation of macroscopic, microstructure and microscopic fracture morphology, the cause of failure is analyzed.

(a) Austenitic Tinned Copper Braided Sleeve

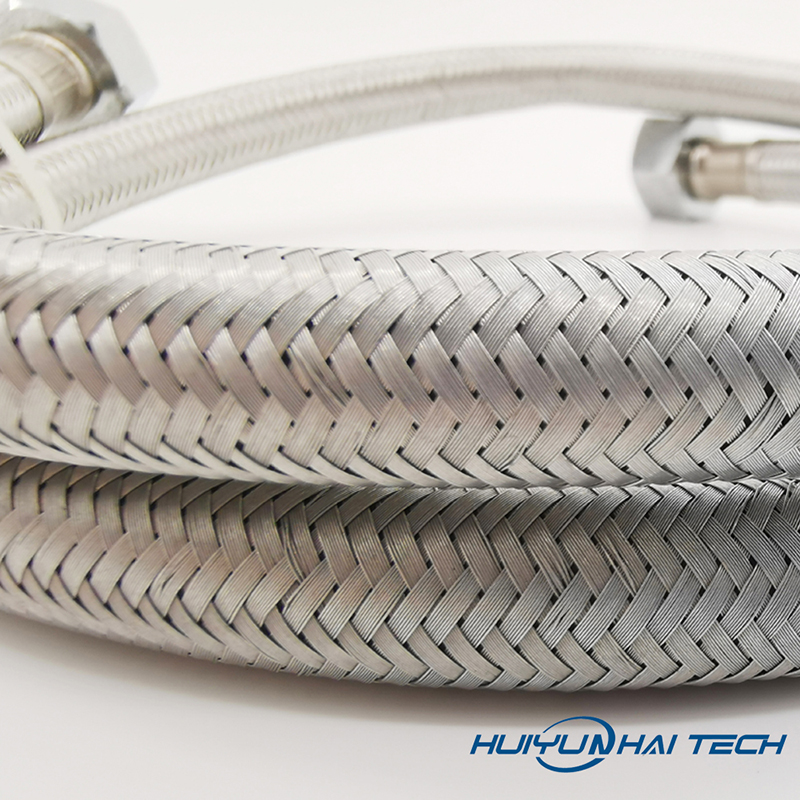

(b) The surface of the tinned copper braided casing is seriously rusted

2. Macro crack analysis

The inner diameter of this batch of failed samples is 20mm, the wall thickness is 0.30mm, and the distance between the crack and the weld is about a quarter of the circumference, as shown in the appearance of the crack. It can be seen that there are many serious rusts on the outer surface of the failed tinned copper braided casing, which shows that the tinned copper braided casing is severely corroded, and there is no obvious mechanical damage near the crack.

Through the fracture morphology, it can be seen that there are cracks on the surface of the steel pipe in some areas, distributed obliquely and parallel, the cracks are wide, and there is obvious shrinkage at the edge of the crack. At the end of the crack, the metal on the outer layer deforms and shrinks, and the crack edge zigzags. On the cross-section of the steel pipe, the structure is equiaxed grain distribution, the periphery is basically round, the matrix structure is austenite + a small amount of ferrite, the local distribution is twinned, and the local grain boundary is widened. When not corroded, there are few inclusions on the surface of the sample, and dense corrosion pits appear on the surface after corrosion, indicating that the corrosion resistance of the steel pipe is very poor.

According to the above analysis, the cracking of tin-plated copper braided casing is corrosion failure. Due to the low Cr content of the steel pipe, it is easy to form a chromium-depleted area, which makes the passivation film fragile in these places. When the passivation film is damaged, some special ions in the water medium, due to its small radius, will It has strong adsorption capacity, and its bond with metal cations is also strong. They will contact with the base metal of stainless steel at the place where the passivation film is damaged, and an electrochemical reaction will occur, making the medium strongly acidic, leading to the dissolution of the base metal and forming Source of pitting corrosion, leading to cracking. In addition, due to the large plastic deformation of the Tinned Copper Braided Sleeve during the forming process, the residual stress in the Tinned Copper Braided Sleeve after deformation is very large; It will bend the Tinned Copper Braided Sleeve, which will cause greater stress in the local area, which will cause stress corrosion in the water medium, and cause the steel pipe to fail and crack after a period of use.

At present, stainless steel is favored by consumers for its excellent corrosion resistance, but some merchants take this as an opportunity to replace the content of Cr and Ni with low-cost manganese, and reduce the content of key elements chromium and nickel below the necessary conditions , while chromium and nickel are the most important elements to ensure the corrosion resistance and other comprehensive properties of stainless steel, which greatly reduces the corrosion resistance of stainless steel; in order to make it have the non-magnetic properties of austenitic steel, it exceeds the standard Manganese is added which reduces its corrosion resistance. Its corrosion resistance is only slightly higher than that of carbon steel. This shoddy, profiteering practice has violated the interests of consumers.

The tinned copper braided casing in this inspection is easy to rust and crack, which will not only cause secondary pollution to the water source during use, but also more likely to cause pipeline burst accidents, leaving more hidden dangers for production and daily use. caused great loss to the family. Therefore, consumers should be vigilant to identify the authenticity of stainless steel.

4 Conclusion

1) The Mn content of this Tinned Copper Braided Sleeve is too high, and the Cr content is low, which cannot achieve the corrosion resistance that stainless steel should have, and the pitting resistance equivalent is too low, which is an inferior product.

2) The cracking and water leakage failure of the tinned copper braided casing is mainly due to stress corrosion failure.