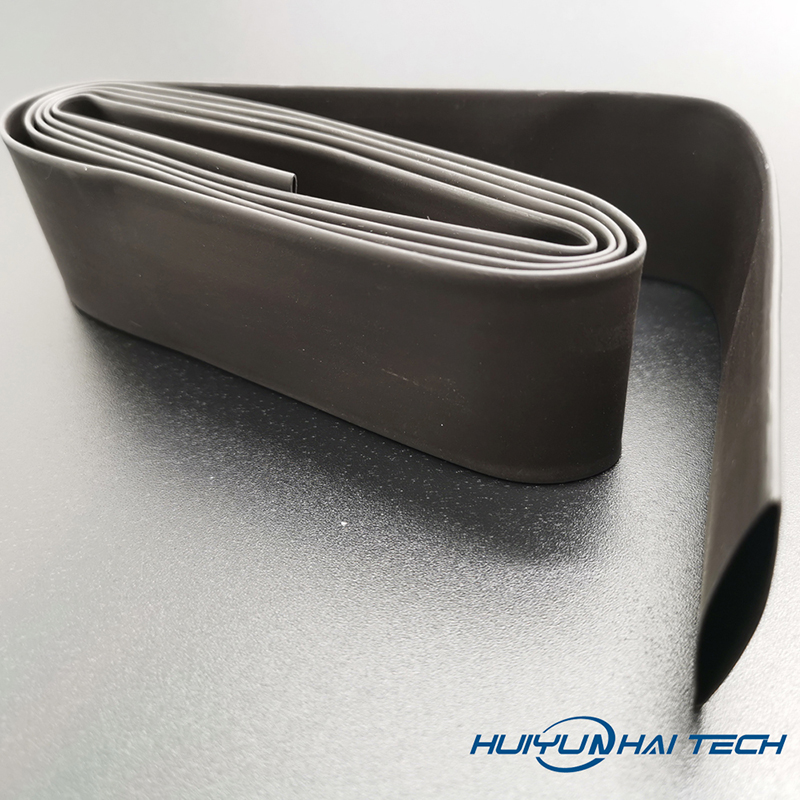

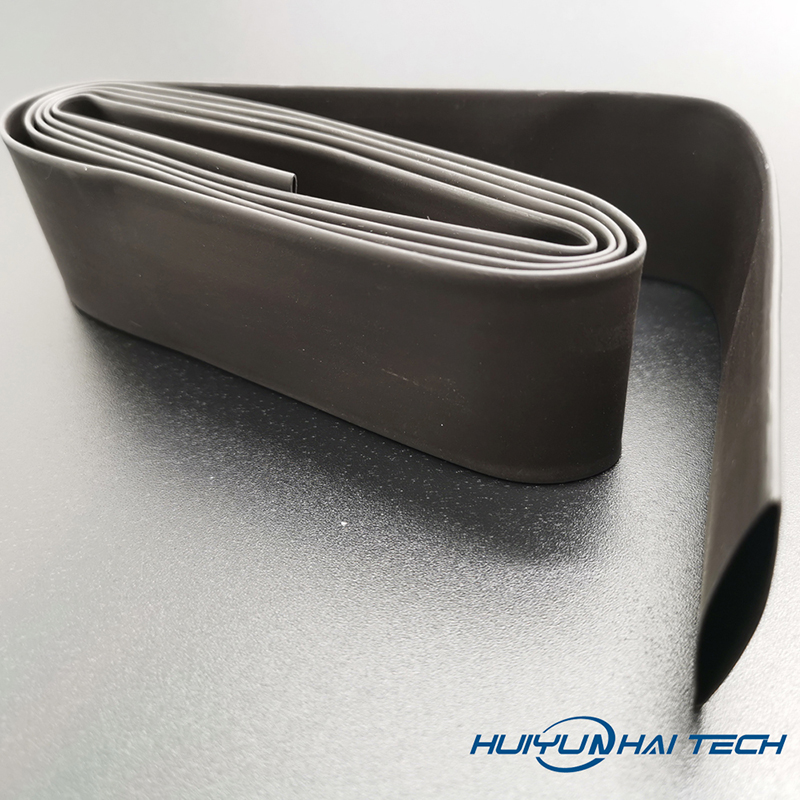

The Automotive Wiring Harness Protection Sleeve has good elasticity and is resistant to aging. In the process of using, will you find that it is easy to spray frost and turn white? What is the reason? Or is it due to the influence of the environment? Of course, we can`t guess randomly. Let`s take a look at the Automotive Wiring Harness Protection Sleeve The causes and protection of the formation of whitening and spraying.

1. Understand the composition of the Automotive Wiring Harness Protection Sleeve

The Automotive Wiring Harness Protection Sleeve is extracted from a white sap in the rubber tree. It is natural and environmentally friendly, non-toxic and harmless, and its basic chemical composition is polyisoprene.

2. The cause of the whitening of the automobile wiring harness protective cover

Frosting and whitening of Automotive Wiring Harness Protection Sleeve refers to the phenomenon that the compounding agent in the rubber material migrates from the inside to the surface. It is mainly due to the formation of supersaturated state or incompatibility of some compounding ingredients in the rubber. For the compounding agent with solubility in the rubber compound, after reaching the supersaturated state, it is always close to the surface layer and the compounding agent is sprayed out of the surface first, so the closer to the surface layer, the lower the concentration of these compounding agents.

3. How to protect the whitening of the Automotive Wiring Harness Protection Sleeve

If you want to reduce the frosting of the Automotive Wiring Harness Protection Sleeve, you should choose raw rubber with high solubility, or try to choose raw rubber with similar solubility parameters to the compounding agent. In the production process of the Automotive Wiring Harness Protection Sleeve, the amount of solvent used should be reduced as much as possible. When the product is fully formed, it can be wiped with a relatively concentrated silicone oil, and then secondary vulcanization can reduce the occurrence of frosting.

It can be wiped dry with a damp cloth without affecting the performance of the tube. What really affects the performance of the pipe is that the pH or temperature is too high to age the pipe.

In short, the Automotive Wiring Harness Protection Sleeve should be wiped clean when it is not in use, and then put it in a black dry bag. Do not expose it to strong light or place it in a humid place, and keep it sealed in a plastic bag if it is not used for a long time.