Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

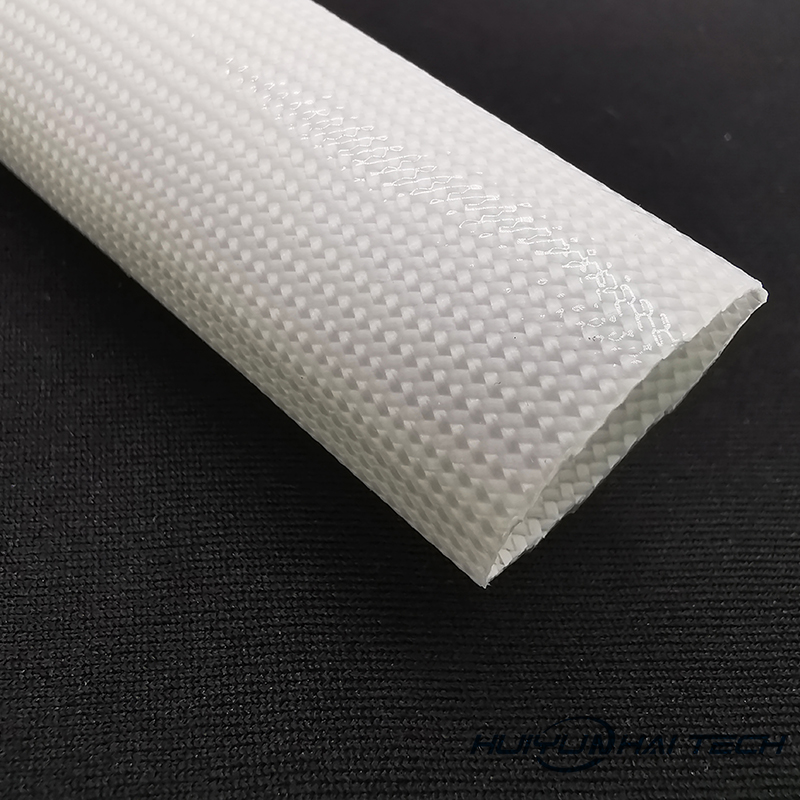

In recent years, Silicone Glass Fiber Tube have been continuously improved, and are developing in the direction of diversification and multi-function in terms of manufacturing process and price. They have been successfully used in many places, such as some mobile phone casings, many mechanical industries will use them, and in order to achieve the final requirements, the back-end process is very important to meet different needs.

October 16, 2024

October 15, 2024

October 16, 2024

October 15, 2024

Email to this supplier

October 16, 2024

October 15, 2024

October 16, 2024

October 15, 2024

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.