Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

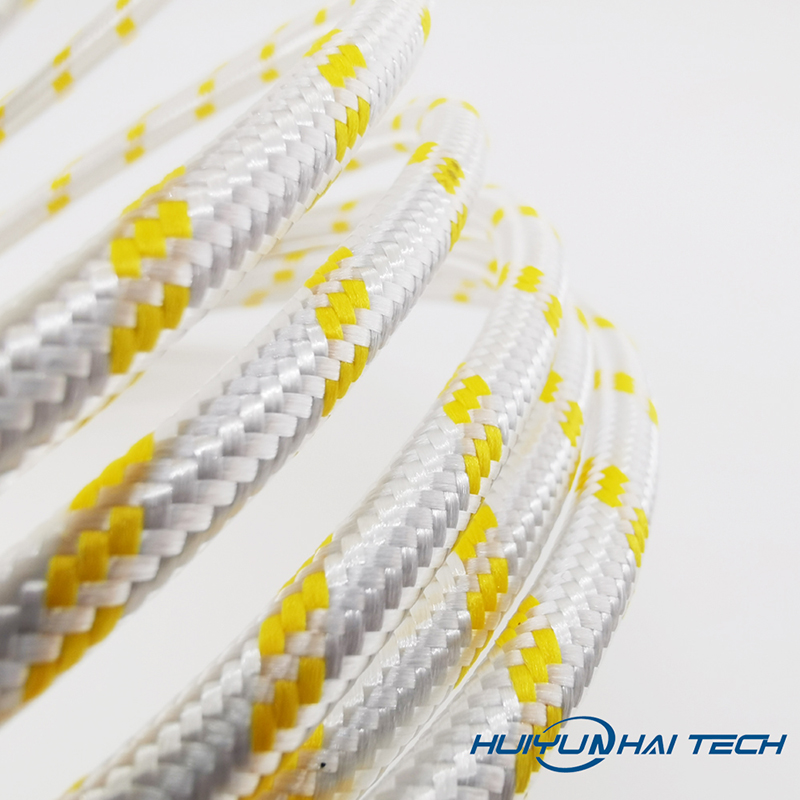

The stress-bearing capacity of polyester/cotton braided sleeves mainly lies in the inner layer and the middle braided layer (polyester fabric extension layer). If the installation is not reasonable during the use process, the airflow will enter the inner layer between the inner layer and the outer layer. At this time, the rubber hose mainly relies on the outer layer to bear the force, which will greatly reduce the stress-bearing capacity of the Polyester/Cotton Braided Sleeve, and cause the tube body to crack (such cracks are usually caused by the outer layer being damaged while the inner layer is intact).

October 16, 2024

October 15, 2024

October 16, 2024

October 15, 2024

Email to this supplier

October 16, 2024

October 15, 2024

October 16, 2024

October 15, 2024

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.