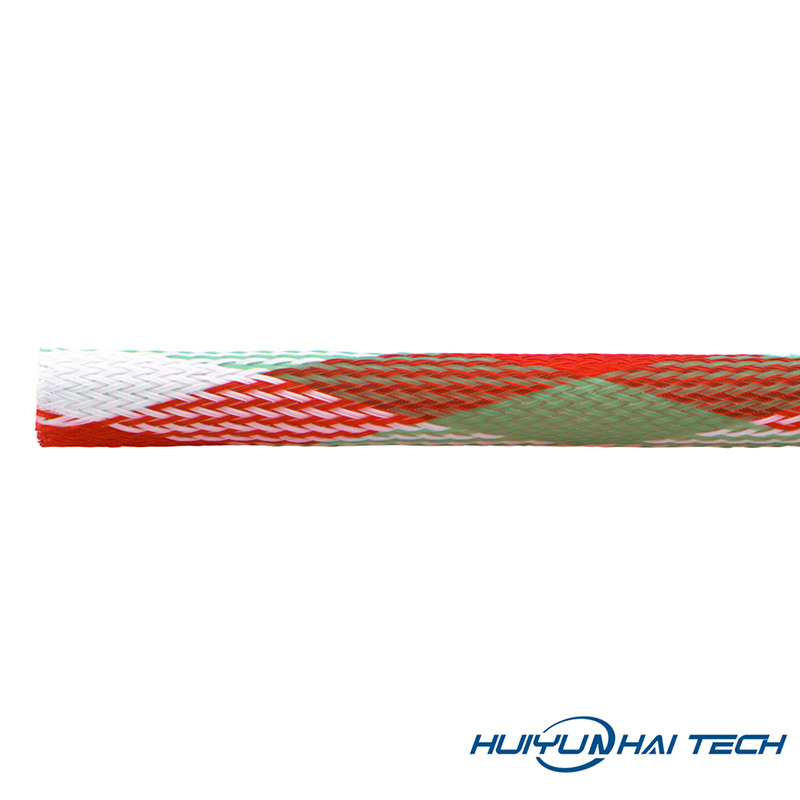

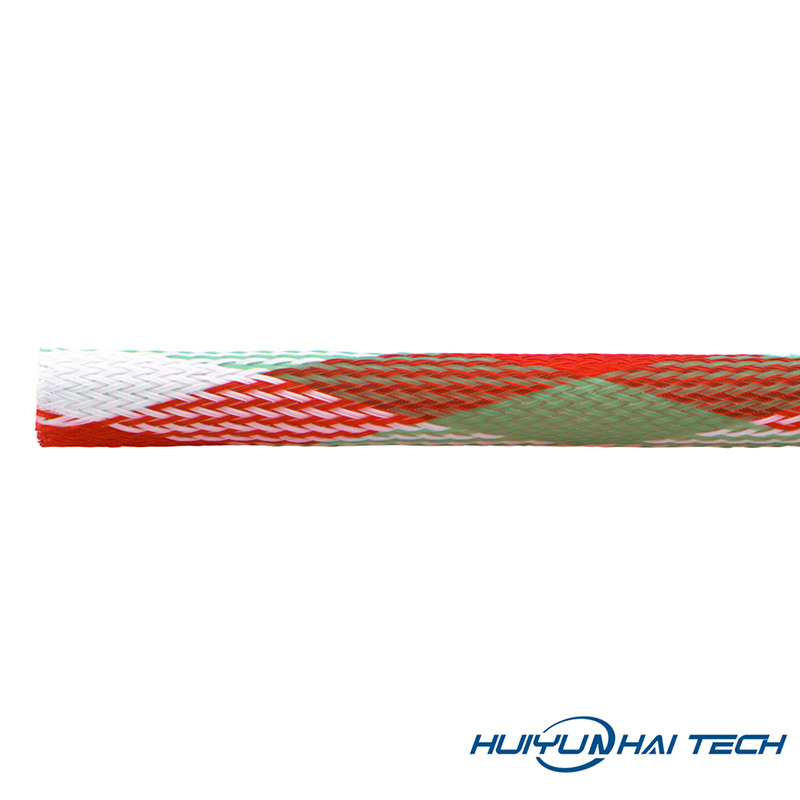

The main material of Nomex Braided Sleeve is the cable sleeving. The appearance of the cable sleeving is easy to be confused. In fact, not only the appearance, but also many problems in the production of the two products are similar. One of them is That is, there will be different colors in the production, which is what the telescopic water pipe manufacturers call dark marks.

First of all, when selecting the raw material of the

Cable Sleeve, it must be strictly controlled. For example, it may be difficult to distinguish the color difference and hardness of two different Cable Sleeve raw materials on the naked eye, but in fact there is still a big difference between the two. The difference is that if these two batches of Cable Sleeve raw materials are mixed and molded, then the quality inspection after molding will find a small color difference, and it will not be shipped, because the quality inspection of our Cable Sleeve is very strict. can only be dealt with in the form of defective products. Therefore, when choosing the raw materials of the Cable Sleeve, it must be sure that there is no mixing. It is very important to know the source. If the head is wrong, all the subsequent processes can only be soy sauce!

Secondly, Nomex

Braided Sleeve is colorless, non-toxic, and tasteless. If you want to make Nomex Braided Sleeve into color, you need to add "color masterbatch". Therefore, the choice of color masterbatch must not be wrong. If the temperature resistance of the color masterbatch is not good, then basically the Nomex Braided Sleeve becomes a waste product, because the color masterbatch needs to be integrated into the Nomex Braided Sleeve for high temperature molding. At this time, the color masterbatch is Nomex Braided Sleeve can be discolored only by melting at high temperature. If the color masterbatch affects the entire production due to poor temperature resistance, the consequences are self-evident, so you must choose the most suitable color masterbatch.

In addition, you should also pay attention to the cutting process of Nomex Braided Sleeve, because if the rubber material is cut too thick or too narrow, it may be inconvenient to vent when cutting, and it will also cause the Cable Sleeve products to be damaged. After forming, the surface color has color difference, so it is also necessary to ensure the best cutting of the product when cutting. Avoiding the phenomenon of dark marks on the Nomex Braided Sleeve can ensure that the qualified rate of the product is improved and the production is more orderly. Another point that the enterprise is very concerned about is that it can reduce the cost of the enterprise. Therefore, when planting elastic tubes, tension rings, and tension Pay attention to the above points when purchasing tablets, fitness tension tubes and other products.