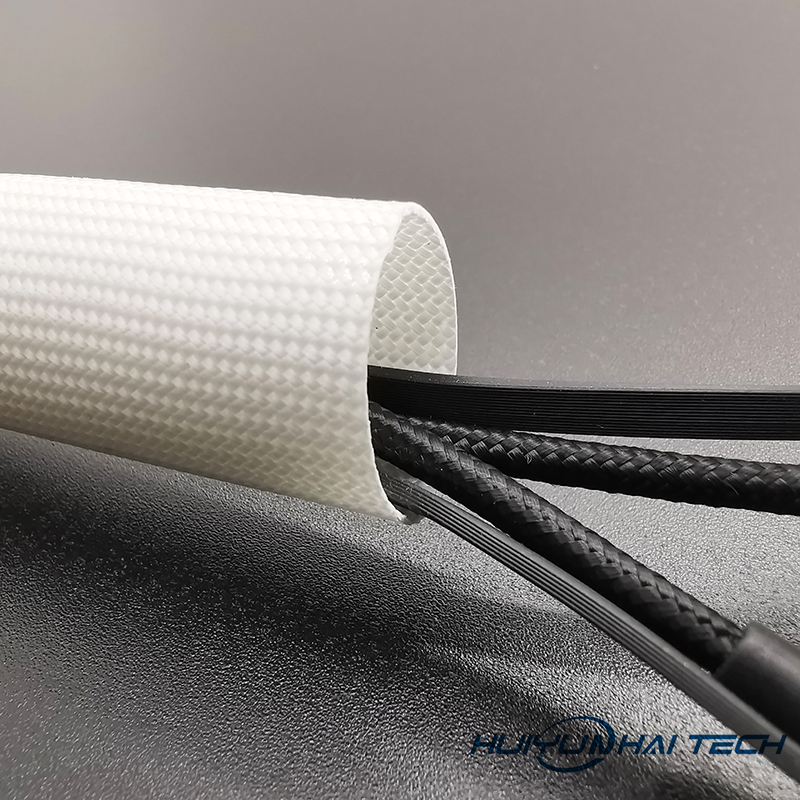

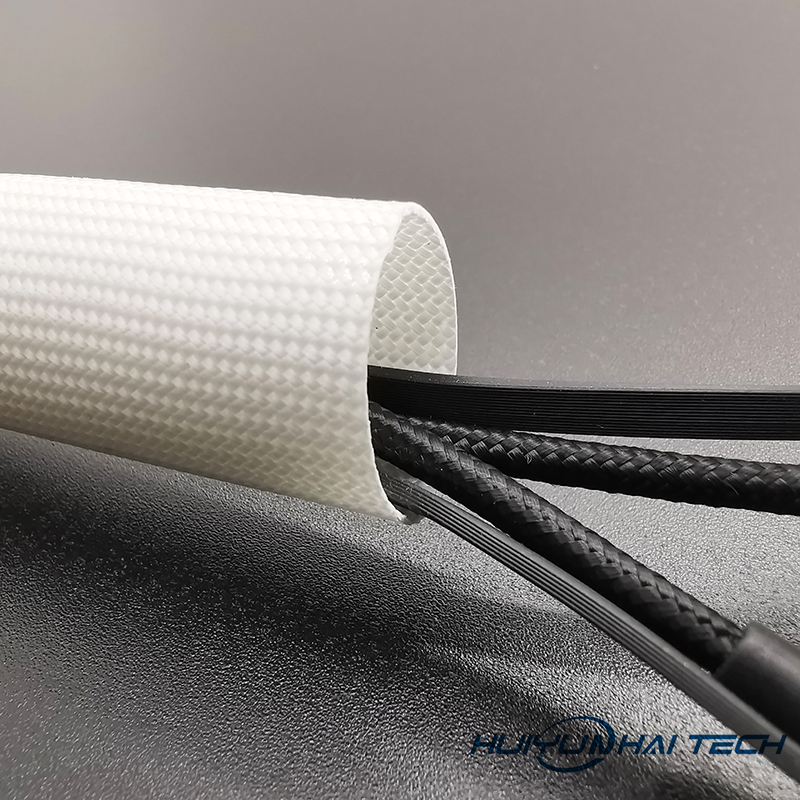

Since the vast majority of Silicone Glass Fiber Tube need to be sealed, waterproof, fixed, and shock-absorbing, it can be said that any part that cooperates with the Silicone Glass Fiber Tube can affect the sealing performance, so when the product is not sealed or leaks When the situation occurs, the product structure engineer needs to conduct a comprehensive review, and cannot start with a single structure, because the sealing is not only something that can be completed by a single part of the Silicone Glass Fiber Tube. When designing the product structure, it is necessary to design different shapes in different Some parts can be designed as B-shaped or 7-shaped or Japanese-shaped. See which structure is more suitable for your product use. Of course, you can also design novel Silicone Glass Fiber Tube for waterproofing.

When designing Silicone Glass Fiber Tube, it is necessary to realize the feasibility of mass production, because we are an insulation tube extrusion manufacturer, and we have contacted a lot of customers, and some of them inevitably have very good structures, but they are difficult to produce. It will cause unnecessary cost increase, so as an actual manufacturer, it is recommended that many engineers must base their designs on the three angles of cost, practicality, and quality. In addition, it is necessary to know that in the actual production process of the

Insulation Tubes, it is not recommended to make a certain sealing groove of the Silicone Glass Fiber Tube too thin or too thin. There are some relatively limited production principles in the production process of the Insulation Tubes. For example: the wall thickness cannot be lower than 0.4 and the curvature cannot be too extreme, otherwise it cannot be established from a production point of view.

There are also some theoretically established Silicone Glass Fiber Tube, which are completely untenable in the actual production process. At present, the better sealing performance of Insulation Tubes should be the series of Insulation Tubes foam sealing strips. You need to consider the foaming density of the Insulation Tubes and the performance of the product. The conventional density of the Insulation Tubes is 1.2. If foaming is used, the density will be disturbed. It can be used from 0.3 to 1.0. The higher the density is, the higher the density is. The higher the hardness, and vice versa, so when designing the structure of the Silicone Glass Fiber Tube, some indicators of the performance of the Insulation Tubes product must be taken into consideration.

Some extreme performance of the Insulation Tubes is also one of the qualified sealing products to verify whether the Silicone Glass Fiber Tube is qualified. At the beginning of the design structure, it is necessary to consider whether the product needs to be sealed in water for a long time, or sealed at high temperature for a long time, or sealed in an airtight environment. Environmentally sealed. Each of these has different performance requirements, which means that the Silicone Glass Fiber Tube needs to be changed accordingly. For example: high temperature resistant Silicone Glass Fiber Tube needs to add high temperature resistant agent in the Insulation Tubes, flame retardant Silicone Glass Fiber Tube needs to add flame retardant, when these auxiliary materials are added to the Insulation Tubes, the performance of the Insulation Tubes will slightly change These changes need to be taken into consideration.