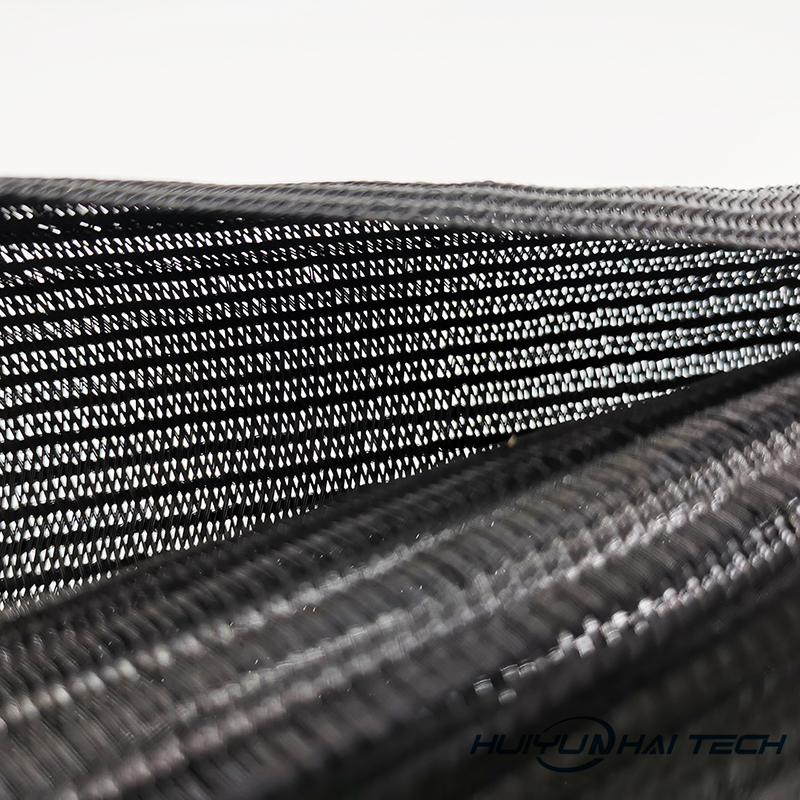

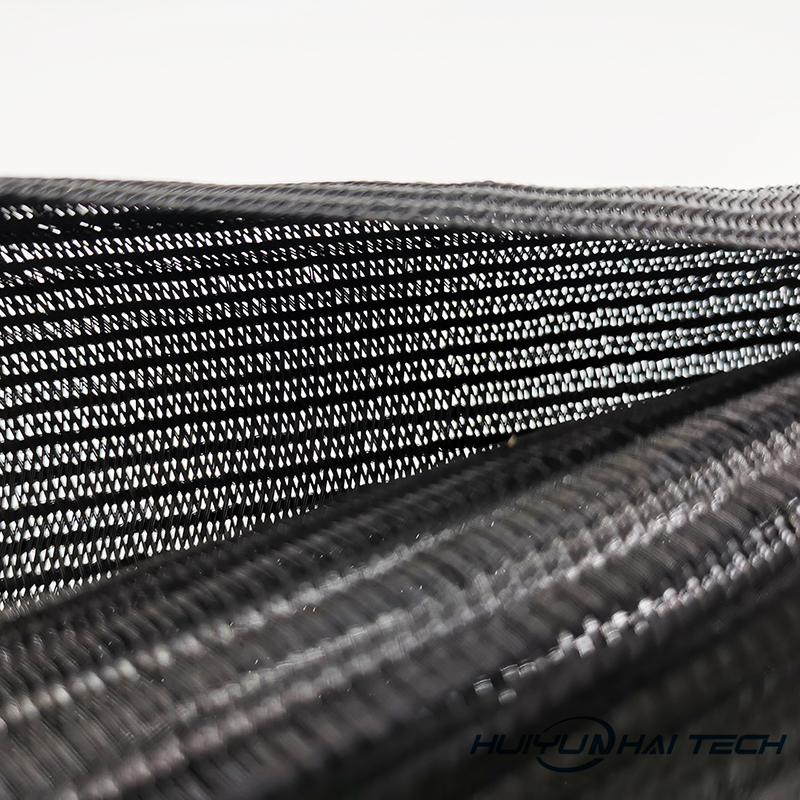

First of all, what are the mainstream production processes of PET Self wrap braided sleeve? As for increasing production capacity, it depends on the products and application fields used by customers.

The first

PET Self Wrap Braided Sleeve process is the method that manufacturers with more

Cable Sleeve production capacity choose to increase production capacity, that is, the Cable Sleeve is extruded at the front end and installed with spraying equipment at the rear end to achieve oil spraying while extruding. The general method is that the silicone rubber is raised at the front end to shape the mold into a round tube shape, and then vulcanized once in a high-temperature oven to make the Cable Sleeve initially formed, and the Cable Sleeve in this link is not sprayed with oil. As a result, the Cable Sleeve enters the 10-meter-long drying tunnel again for vulcanization and molding until the end is shipped. Generally, the extrusion of silicone has been completed so far, while the

Pet Self Wrap Braided Sleeve enters the spraying drying tunnel again for further processing. One coat spray treatment. This is the current mainstream "extrusion + oil injection" integrated extrusion process. As for the production capacity, it is also a relatively fast one. It is suitable for high-volume products with PET Self Wrap

Braided Sleeve as appearance parts, such as silicone sleeves for desk lamps. , hanging neck fan cable casing, magnetic data cable silicone sleeve and a series of products. Therefore, online extrusion oil injection is one of the primary options for increasing production capacity.

The advantage of online PET Self Wrap Braided Sleeve is that the shipment quantity is stable. According to the production capacity of an extruder equipped with spraying equipment, it can reach 10,000 meters/12 hours. The average production capacity of PET Self Wrap Braided Sleeve for one hour is enough Reaching 1000 meters, if according to the day and night shift, the daily production capacity is close to 20,000 meters per day, and we are equipped with 14 extrusion production lines that can flexibly handle various large orders and various emergencies at any time. If conditions permit, one The production line is not enough to meet the needs of customers and we will add several online oil injection extruders. The second advantage is that the PET Self Wrap Braided Sleeve under this process can achieve a consistent silky smoothness, which is suitable for some appearance parts. Why do you say that? That's because the spraying equipment is programmed during the online spraying process, the average sprayed ink per minute is set and the usage is also controlled by the machine, so the cable casing that has been sprayed online has this balance It feels silky and smooth to the touch from the beginning to the end.

The production capacity of the other PET Self Wrap Braided Sleeve process is slightly lower, which is also a relatively primitive method, that is, the Cable Sleeve is first produced according to the extrusion step, and the production capacity at this time is faster than that of the online spraying process. After all It is made without adding online spraying equipment, and semi-automatic spraying is carried out after the cable casing is extruded and cooled. The production capacity of one class of this method is estimated to be between 5000 and 6000 meters, which is somewhat different from the online spraying process, but this semi-automatic PET Self Wrap Braided Sleeve is used in special fields, such as some silicone lampshades and special-shaped cables Sleeves, special-shaped silicone strips, etc. The reason why these products need to be sprayed is because they are appearance parts or non-appearance parts, but they must have certain functions. Some semi-automatic oil injection processes are not only cable casings External, calendering, molding and other processes can be used.

Combined with online oil injection, it is more suitable for Cable Sleeve and has higher production capacity, and most of them feel silky and soft. On the contrary, the production capacity of semi-automatic PET Self Wrap Braided Sleeve is generally more exquisite, and most of them have some kind of Special performance cable bushings will be selected.