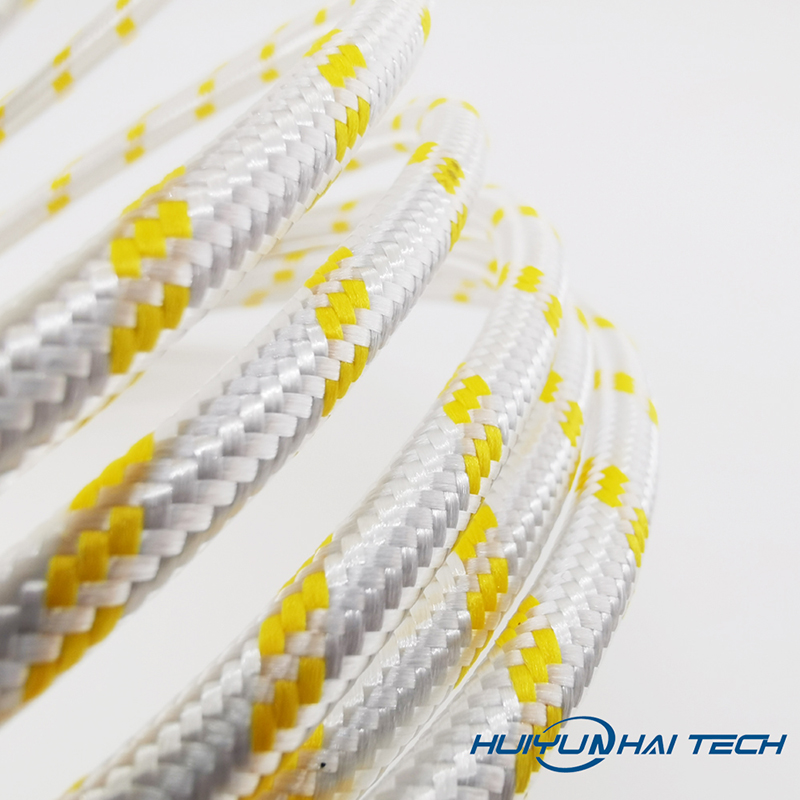

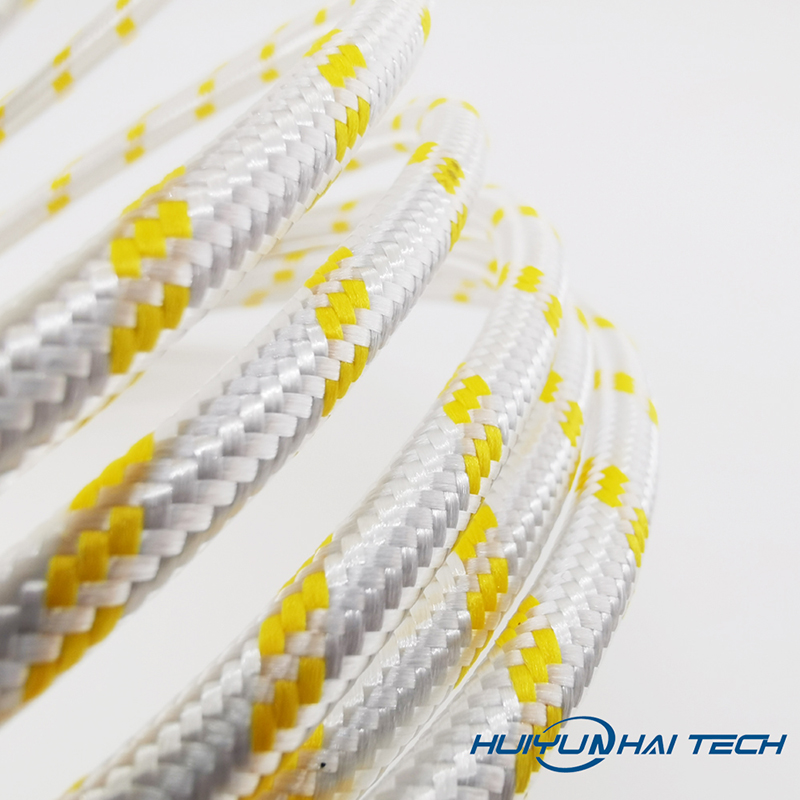

According to the shape of Special Material Braided Sleeve, it can be divided into: spiral wave and ring wave. Spiral wave saves material, and the tube is light in weight, but the tube is hard and not easy to bend. Ring wave has good flexibility and is very popular among users. But because it weighs nearly half as much, the price will be relatively higher.

Aluminum Heat Reflect Fiberglass Hose are very long before production, with tens or even hundreds of meters placed there. Cut according to the length required by the customer. The length of the pipe is controlled at this time. Some unscrupulous manufacturers lower prices in order to gain profits. The Special Material

Braided Sleeve will be lengthened.

Because the products sold to customers are calculated based on length. In this way, one meter of Special Material Braided Sleeve can be sold for one meter to one meter two. Others use small-sized Special Material Braided Sleeve and fine mesh sleeves. Compared with others, it is about three to five millimeters smaller with the same specifications.

Of course, some people think that the smaller the inner diameter of the pipe, the greater the pressure it will bear. Due to the diameter of the connectors at both ends, a large inner diameter of the pipe may not be useful. However, the practice of thinning pipes is still condemned.

Cut off the Special Material Braided Sleeve and put them on the net sleeves together. Put sheaths on both ends to prevent the mesh from unraveling. Weld the Special Material Braided Sleeve and mesh sheath first. Then put the required nut on the cannula and perform secondary welding. The skill of the welding master can be seen from the welding joint.

After welding, polish the welded area. If it is not polished, you will see that the color of the welding joint is different. Do not touch water when the temperature is high, otherwise it will easily rust. The most taboo when using hoses is that the length and curvature of the hard-drawn hose is greater than 45°. Causes stress on the hose welding joint. Eventually the hose leaks. Therefore, when choosing Aluminum Heat Reflect Fiberglass Hose, you must add three to five centimeters to the actual length required. A hose with a little bend will last longer.

When connecting the Aluminum Heat Reflect Fiberglass Hose to the transition joint, the threads must be tightened parallel. It is best not to disassemble and assemble frequently after tightening. When the equipment is subject to vibration, the length of the Aluminum Heat Reflect Fiberglass Hose must be lengthened. Do not allow objects to press onto the hose. Do not allow hot water or chemicals to get on the surface of the hose. Aluminum Heat Reflect Fiberglass Hose will also rust when exposed to cold water at high temperatures. Reduce hose life.