The quality of the Stainless Steel braided sleeve directly affects the normal use of the Cable Sleeve, so it is necessary to pay attention to the quality inspection of the Stainless Steel Braided Sleeve. The editor of the Stainless Steel Braided Sleeve manufacturer made a brief introduction from several aspects.

Stainless Steel Braided Sleeve should pay attention to quality inspection. Since the diameter of the Stainless Steel Braided Sleeve and the outer diameter of the skeleton layer are not strong, if the vibration scale exceeds the promised limit, the balance of the adhesion of the Cable Sleeve joint cannot be ensured, and it is difficult to ensure the quality of the Cable Sleeve assembly. Therefore, regarding the production of rubber cable bushing components, it is necessary to strictly check whether the inner diameter and outer diameter of the structural layer meet the requirements.

Due to the pain of the rubber layer in the Stainless Steel Braided Sleeve and the influence of the joint width between the structural layers of the quality inspection center of the Stainless Steel Braided Sleeve, the error in the thickness of the pipe wall is too large. If the wall thickness error exceeds the allowable range, it will affect the sealing ability and tensile strength of the rubber Cable Sleeve assembly, and even cause some deflection of the joint of the rubber Cable Sleeve assembly. Therefore, the quality inspection of Stainless Steel Braided Sleeve should strictly control the wall thickness error of the cable casing. Generally, Cable Sleeve with a wall thickness of more than 0.5 mm should be strictly selected.

The Stainless Steel Braided Sleeve should have good integrity, that is, the quality inspection of the Stainless Steel Braided Sleeve: each structural layer should have high adhesion, and the glue between each layer should form a whole. This kind of talent is used for various skill requirements in the joint installation and fastening process, and can ensure the high voltage and power quality inspection requirements of rubber cable bushing installation. Therefore, it is necessary to control the adhesion between the layers of the rubber Cable Sleeve not to be lower than the technical standard, and to select a high-adhesion rubber Cable Sleeve to produce rubber Cable Sleeve parts.

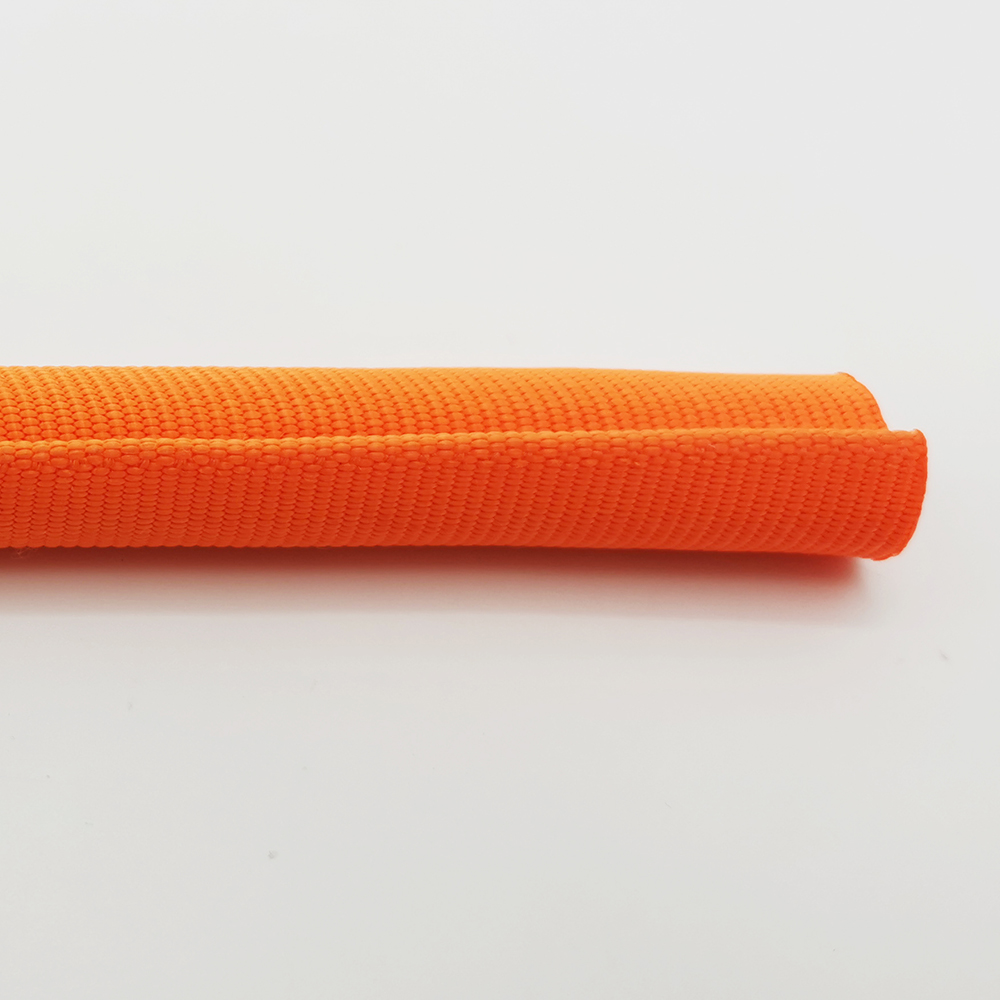

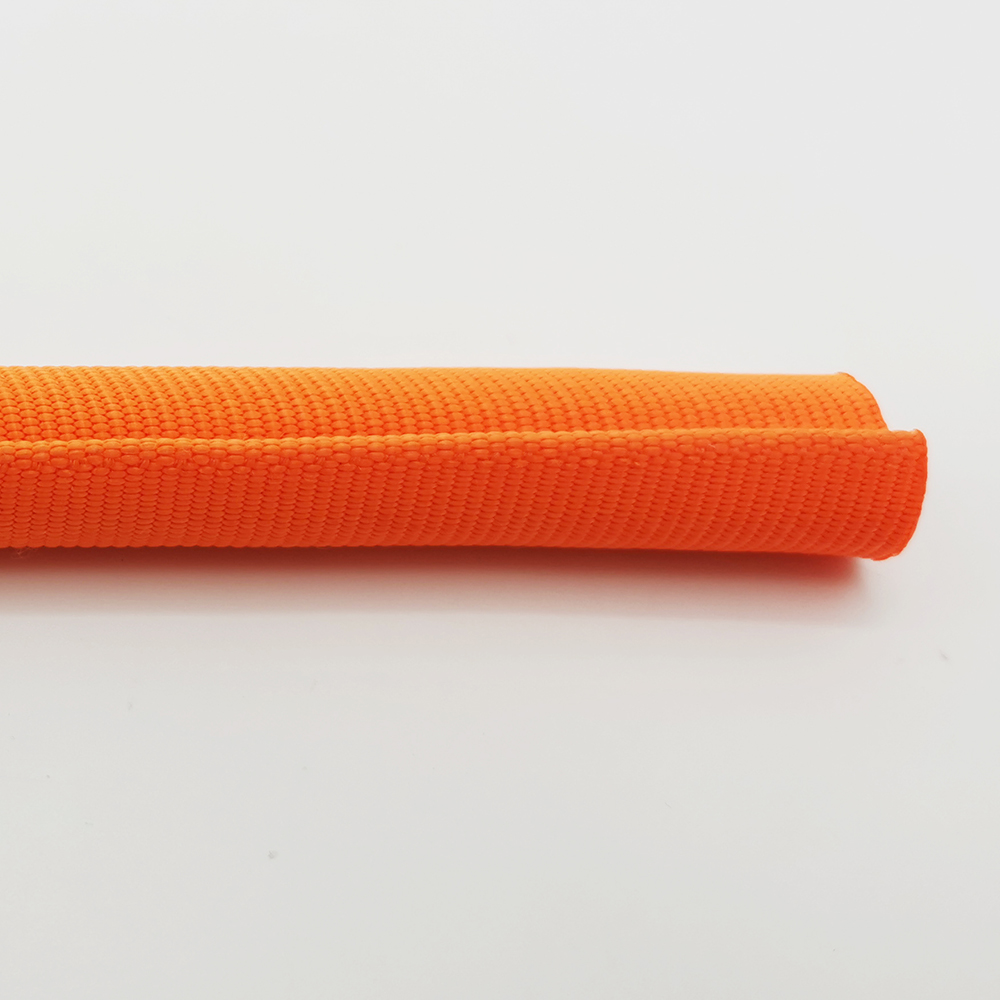

The appearance quality of Stainless Steel Braided Sleeve cannot be ignored. It not only affects the appearance quality of Stainless Steel Braided Sleeve components, but also affects its use quality. If there are air bubbles, pores or mechanical damage in the rubber, the skeleton layer and the skeleton layer will form corrosion, which will reduce the shrinkage strength of the Cable Sleeve, directly affect the service life of the Cable Sleeve assembly, and may even occur during use. Therefore, attention should be paid to the appearance and quality of the Cable Sleeve, and the appearance defects that affect the quality inspection of the Stainless Steel Braided Sleeve assembly should be eliminated.