Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

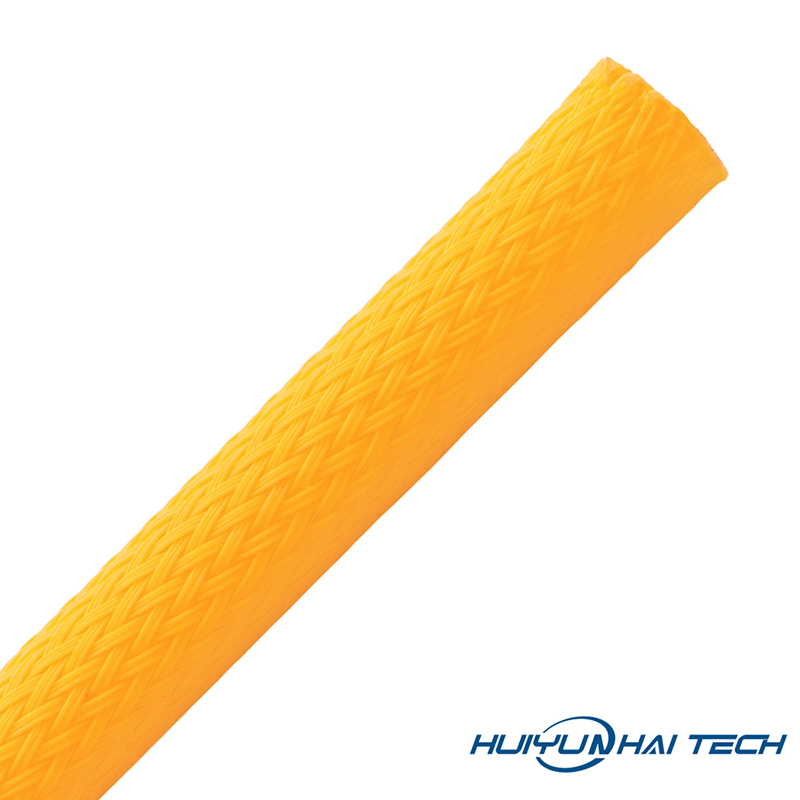

Fire Proof Silicone Glass Fiber Braided Hose is an accessory of peristaltic pump, mainly used to transport liquid, gas, liquid and mixture of gas and solid. Fireproof silica gel glass fiber Braided Cable Sleeve has certain elasticity, wear resistance, ability to withstand pressure, no leakage (good air tightness), low adsorption, good temperature resistance, not easy to aging, no swelling , Anti-corrosion, low precipitates and so on. However, in the process of use, due to the incorrect installation of the Fire Proof Silicone Glass Fiber Braided hose or the corrosiveness of the liquid, the Cable Sleeve pump will be prematurely worn and abnormally worn. What are the main factors?

October 16, 2024

October 15, 2024

October 16, 2024

October 15, 2024

Email to this supplier

October 16, 2024

October 15, 2024

October 16, 2024

October 15, 2024

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.