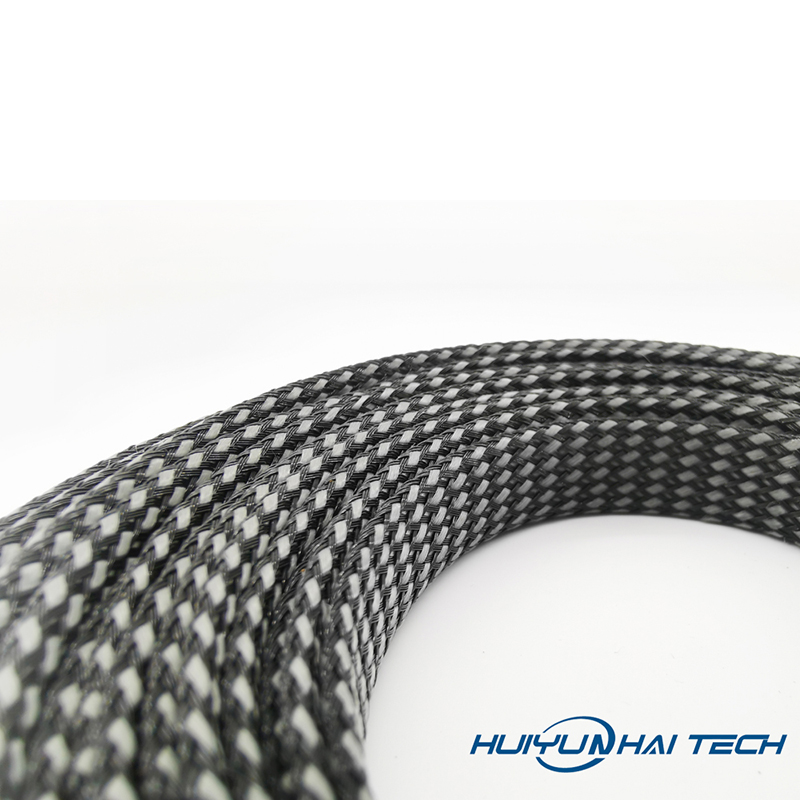

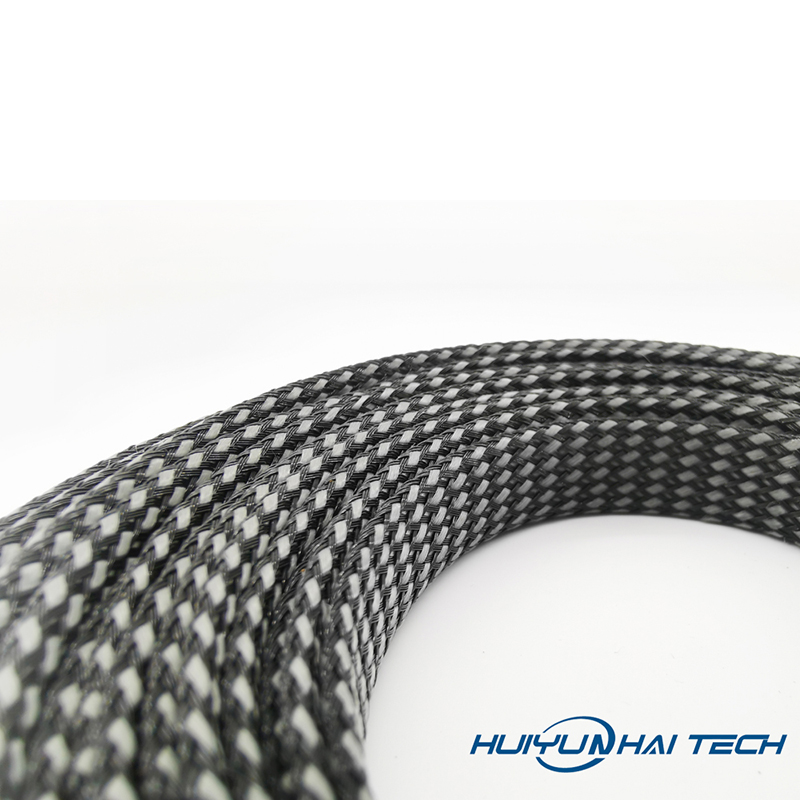

Heat Shrinkable Braided Sleeve are a kind of pipe material used in special environments or special process requirements. They are usually used in chemical, petroleum, natural gas and other industries. Due to its special uses and environmental requirements, the product standards of Heat Shrinkable Braided Sleeve are also relatively high. Below we will introduce in detail the product standard requirements of Heat Shrinkable Braided Sleeve.

First of all, the material requirements for Heat Shrinkable Braided Sleeve are very strict. According to different use environments and process requirements, Heat Shrinkable Braided Sleeve are usually made of stainless steel, alloy steel, nickel alloy and other materials. These materials have excellent corrosion resistance, high temperature resistance and pressure resistance, and can meet the needs of use in various special environments.

Secondly, the size and wall thickness of Heat Shrinkable Braided Sleeve also have strict requirements. According to different usage scenarios and process requirements, the size and wall thickness of Heat Shrinkable Braided Sleeve need to be designed and manufactured in accordance with relevant standards. Normally, the size and wall thickness of Heat Shrinkable Braided Sleeve need to comply with international standards or industry standards to ensure their safety and reliability during use.

In addition, the surface treatment and connection method of Heat Shrinkable Braided Sleeve are also important contents of product standards. Since Heat Shrinkable Braided Sleeve are usually used in special environments or special process requirements, their surface treatment and connection methods need to be designed and selected according to specific usage requirements. Usually, the surface treatment of Heat Shrinkable Braided Sleeve requires anti-corrosion coating or heat treatment to improve its corrosion resistance and wear resistance. At the same time, the connection method of the Heat Shrinkable Braided Sleeve also needs to comply with relevant standards to ensure the firmness and sealing of its connection.

Finally, quality control and testing of Heat Shrinkable Braided Sleeve are also important aspects of product standards. In order to ensure that the quality and performance of Heat Shrinkable Braided Sleeve meet requirements, strict quality control and testing are usually required. This includes the testing of raw materials, control of the production process, and inspection of finished products to ensure that the quality and performance of the Heat Shrinkable Braided Sleeve meet standard requirements.

In general, the product standards for Heat Shrinkable Braided Sleeve are very strict, involving many aspects such as material, size, wall thickness, surface treatment, connection method, quality control and testing. Only by strictly complying with these standard requirements can the safe and reliable use of Heat Shrinkable Braided Sleeve in special environments or special process requirements be ensured.