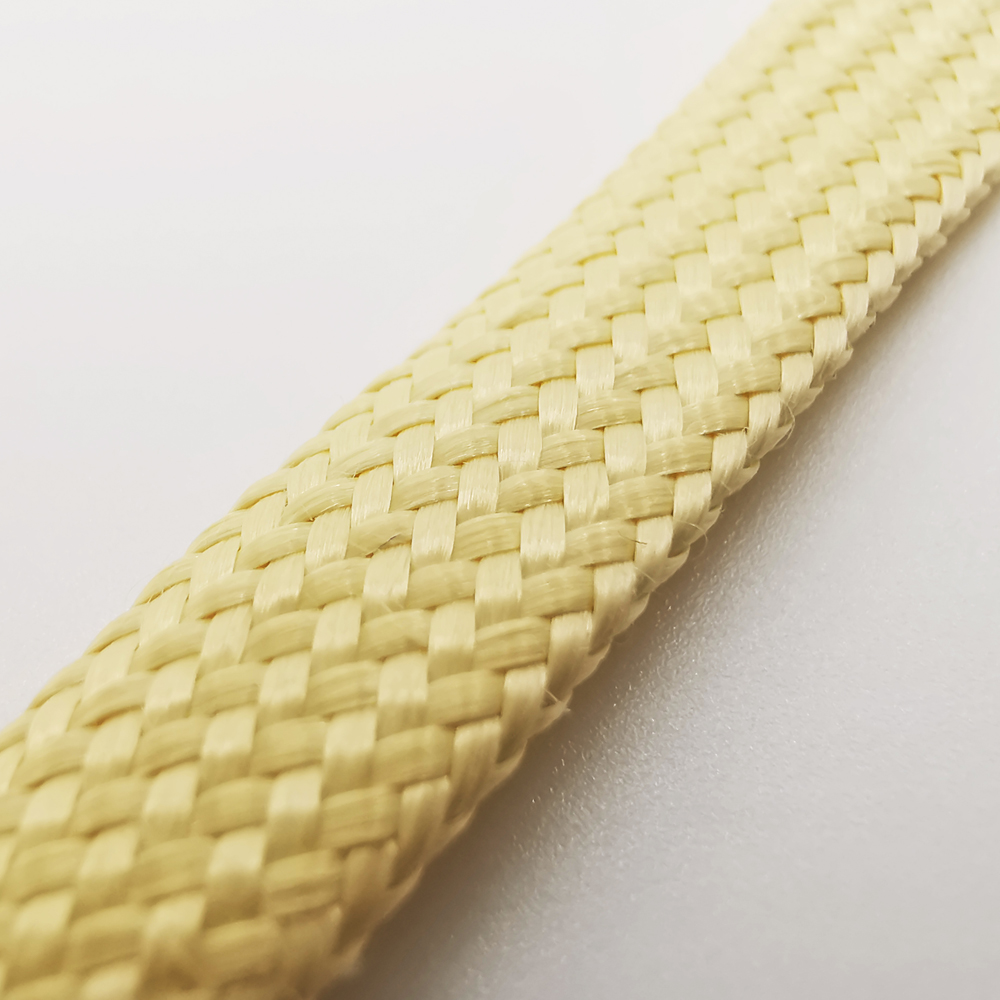

With the hot weather, apart from the air conditioner, the only thing that can bring us a little bit of coolness in summer is ice cubes? With the development of the industry, there are many ice-making molds for Open Type Braided Sleeve. PP Velcro Braided Sleeve are one of them. In recent years, with the increasing popularity of Pp Velcro Braided Sleeve, many consumers Doubts arise, whether its quality will be harmful to the human body, how to choose?

PP Velcro

Braided Sleeve are currently a relatively fierce competition in the entire Open Type Braided Sleeve kitchen industry. Therefore, it has also led to the competition of many PP Velcro Braided Sleeve mold manufacturers and the integration of different industries, resulting in the emergence of products. Open knit sleeve materials, soft plastic and other rubber materials make it difficult for consumers to identify whether they belong to Open knit sleeves, and the market competition for Open knit sleeve kitchens also allows businesses to take advantage of low-cost prices. How to achieve the guarantee of genuine products has become a big knot of many consumers. Today, I will explain to you the advantages and disadvantages of PP Velcro Braided Sleeve molds.

The Open Type Braided Sleeve is essentially a soft colloid, and its advantage lies in the material properties. In the rubber and plastic industry, the Open Type Braided Sleeve material is a kind that highlights the awareness of environmental protection and safety. In the entire rubber and plastic industry, the Open Type Braided Sleeve material is The material characteristics are also one of the more dominant ones. At present, in addition to Open Type Braided Sleeve, ice hockey molds can also be matched with food-grade PP plastic materials. The biggest difference between Open Type Braided Sleeve and plastics is the temperature difference. Open Type Braided Sleeve can withstand high temperatures up to 260 degrees. Plastic PP materials There will be a phenomenon of dissolution when it reaches above 160, and their raw materials are divided into different compounds, so its advantage is that there will be no reaction conflicts under any environment and temperature!

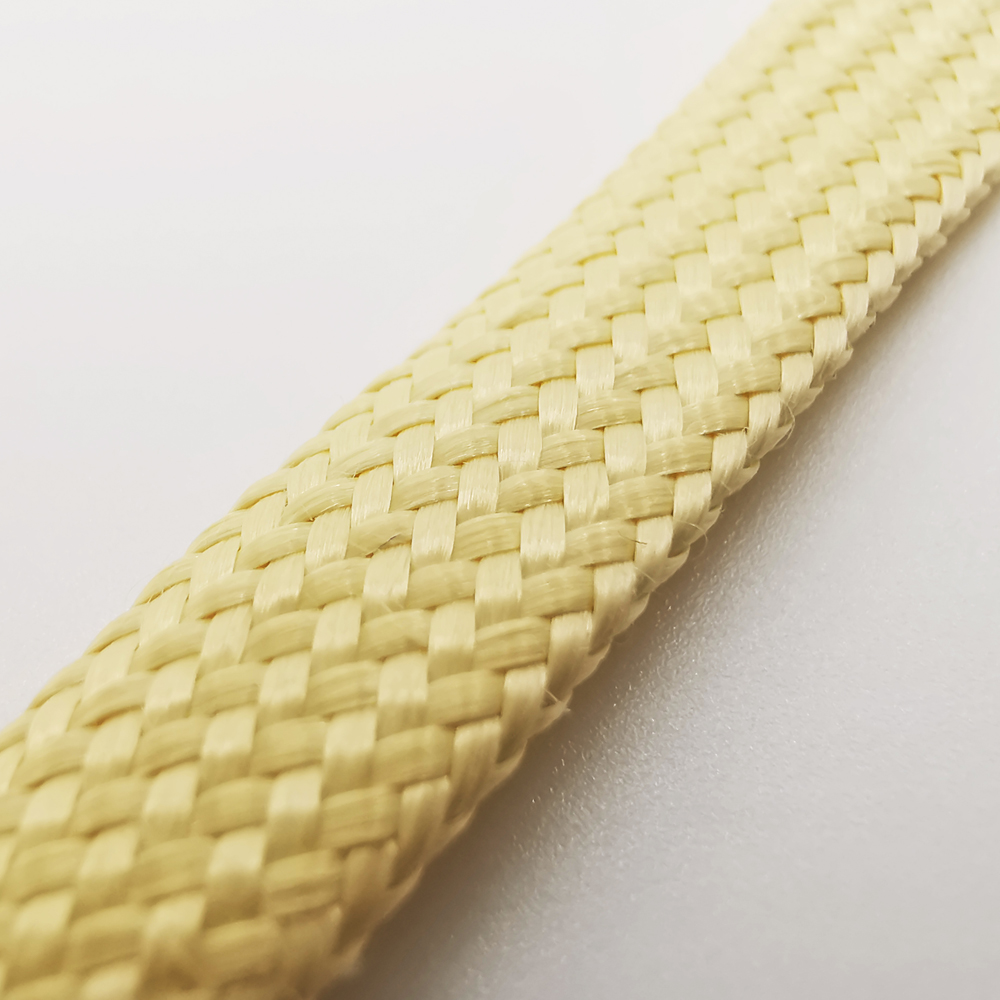

In addition to PP materials, there are currently many soft rubber types that are very similar to Open Type Braided Sleeve. This is the main factor that confuses many consumers. According to personal surveys, in fact, many food-grade PP currently on the market Velcro woven sleeves are all under the banner of Open Type Braided Sleeve materials, but they sell products made of thermoplastic materials. For non-professionals, it is impossible to detect the difference between them, but professionals can recognize the difference at a glance. .

The currently known types of thermoplastic soft rubber are: TPE, TPR, PVC, PU, TPO, etc., which are similar to the materials of Open Type Braided Sleeve. Most of their materials are plastics, but they have the same softness as Open Type Braided Sleeve. Quality effect, but there is a big difference in performance, so if you can personally inspect the product when purchasing, you can judge according to the characteristics of the material, so as to avoid buying a product that is not the PP Velcro Braided Sleeve mold you want!