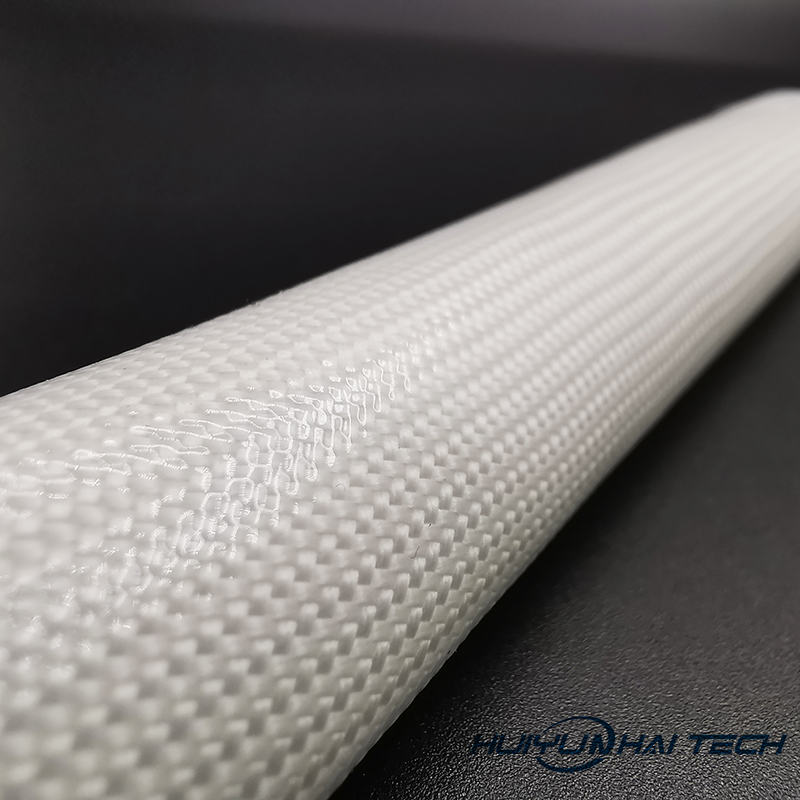

With the popularity of Silicone Glass Fiber Tube daily necessities, more and more household products are replaced by Silicone Glass Fiber Tube materials. The main reason for the replacement is that the Silicone Glass Fiber Tube has certain unique properties, and the folding function for convenient storage is one of them. One, it can not only achieve the functions of storage, folding, and portability, but also can be carried at any time to reduce the use space, which is very suitable for places with space pitch.

Nowadays, a series of products such as foldable Silicone Glass Fiber Tube bowls and foldable Silicone Glass Fiber Tube cups have occupied a certain sales share in the market, so its product folding is also closely related, and this folding function also has a certain core technology Problems, such as drawings, molds, and manufacturers will all have a certain impact on folding. Today, let`s learn where its core functions are reflected.

The core function of the Silicone Glass Fiber Tube folding product is mainly in the design, so when designing the drawings of the

Insulation Tubes, if the folding problem cannot be controlled well, it will cause the folding function to fail. Its folding point mainly lies in: the folding position The thickness determines the folding function of the product.

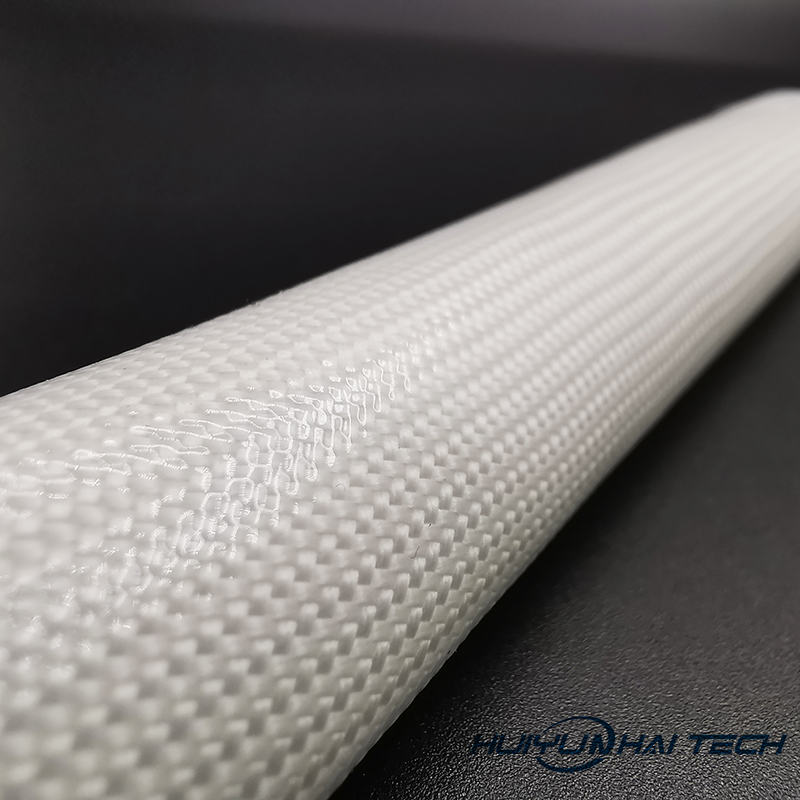

In the middle of each layer of folding pads, the gradient of the interval and taper depends on its functionality. Generally, the thinnest point of the wall thickness is about 0.5-0.8MM, and the taper is generally about 10-20 degrees as a whole. Adjust according to different products and different wall thicknesses of products.

For example: when folding the Silicone Glass Fiber Tube folding bowl, it must be stressed on both sides of the thinnest point, and it can be turned over with a little force, and the turning force must be turned by the inclined wall thickness, so these two points It is its main core problem. After mastering these two skills, different types of designs can be realized!

The mold for the production of folded Silicone Glass Fiber Tube cups for Insulation Tubes is also a major factor. For example, if the mold is not uniform at the minimum folding position or the size tolerance of the entire circle is too large, it is likely to cause damage to the folded position of the Silicone Glass Fiber Tube product or one side. It cannot be pressed down, so there are certain problems with the mold!

Secondly, it is the production situation of the Silicone Glass Fiber Tube manufacturer. The hardness of the product and the debugging of the machine may cause problems with the folding cup. For example, the hardness of the product is mostly between 40-60 degrees. If it can be improved as much as possible, too soft will affect the folding. Secondly, the same is true when the product is produced and vulcanized. If the product is released from the mold in advance or is not fully formed and the product is soft, it is likely to appear soft and cannot be folded.