With the popularization and application of silica gel glass fiber tubes in daily life, more and more industries use silica gel as the main material for customized processing of product categories. However, different Insulation Tubes and fields of use lead to defects and problems in products , bothering many consumers, for example: the whitening of the surface of the silicone product after stretching is one of them, so under what circumstances will the product appear whitening?

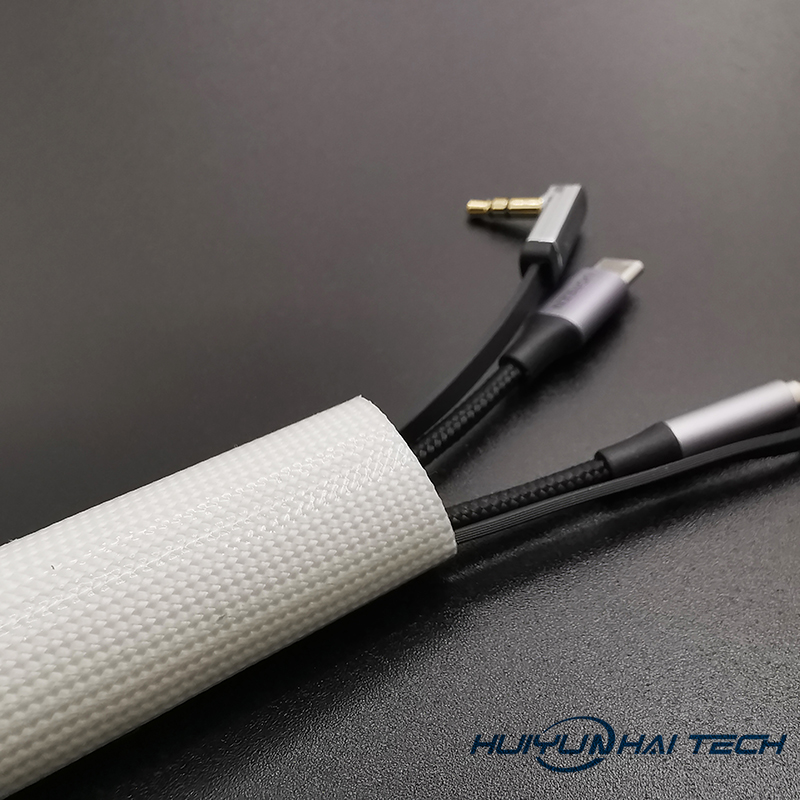

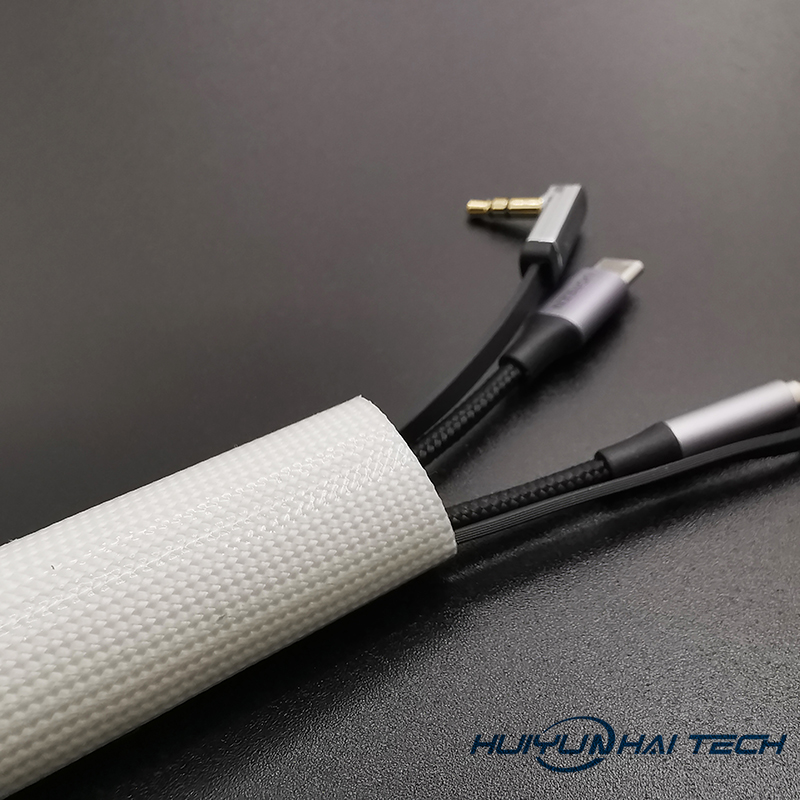

It is normal for the

Silicone Glass Fiber Tube to turn white when it is stretched and twisted. Some friends may be misled and think that the product is white. Let's take a look together.

First of all, the raw material of silica gel is a semi-permeable white mist material, so the whitening of the product after stretching is mainly related to the raw material. The Insulation Tubes is mainly divided into ordinary silica gel, gas phase silica gel, medical silica gel, and special silica gel. And different grades of materials can be seen from the stretch to see what kind of material they belong to.

The main reason for the whitening of the product is: it belongs to precipitated silicone rubber, and the material is mainly due to precipitated silica. This silica is mainly composed of industrial water glass obtained by the reaction of quartz sand and soda ash under the action of high temperature. Prepare a dilute solution with water. Under the condition of epoxy, add the compound to complete the precipitation. After washing, drying and crushing, the precipitated silica is obtained, so its product appears foggy and whitish, mainly because there is a certain amount of silicon in the silicon molecular chain. Caused by the compound, whitish phenomenon occurs when stretched.

In addition to precipitated silicone rubber, silica gel also has gas phase silica gel. Compared with precipitated silica gel, this material has more outstanding performance, which is what we often call food-grade Insulation Tubes. It has higher purity and stronger silicon molecular structure , made of silicon tetrachloride and air-burned silica, the fineness of silicon molecules can reach 800-1000 mesh, ordinary precipitated silica gel is about 400-600, and gas phase silica gel will not appear white fog when stretched shape.

Therefore, when we distinguish silica gel, we can distinguish whether it belongs to ordinary silica gel or food-grade silica gel from these problems. Normally, ordinary silica gel will appear foggy on the surface after being molded and vulcanized by the silica Silicone Glass Fiber Tube. Phenomenon, while the performance of gas-phase silica gel and the purity of raw materials are superior, and there will be no whitening phenomenon when stretching and rebounding.