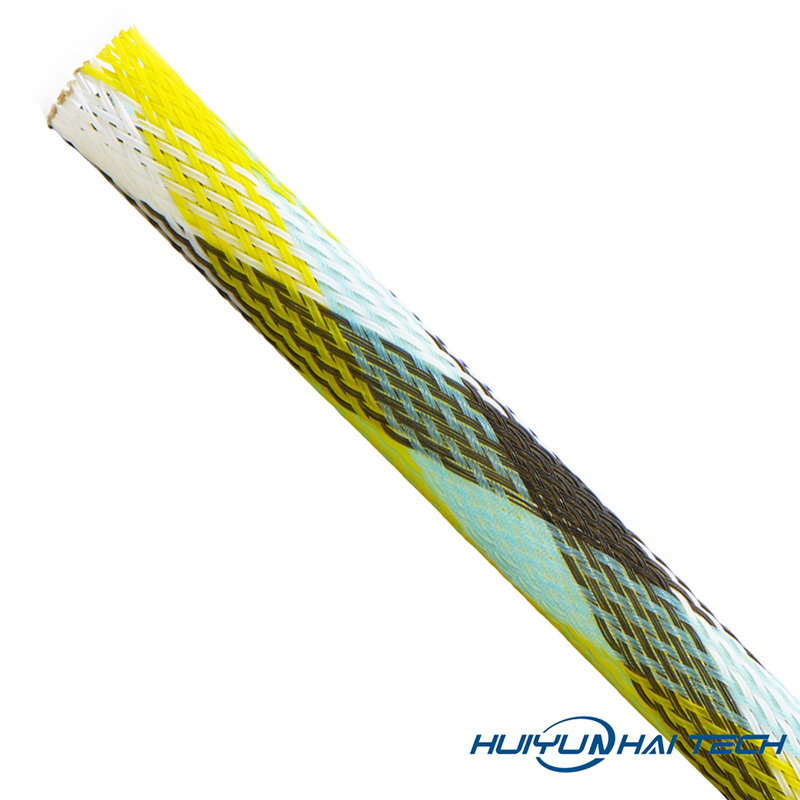

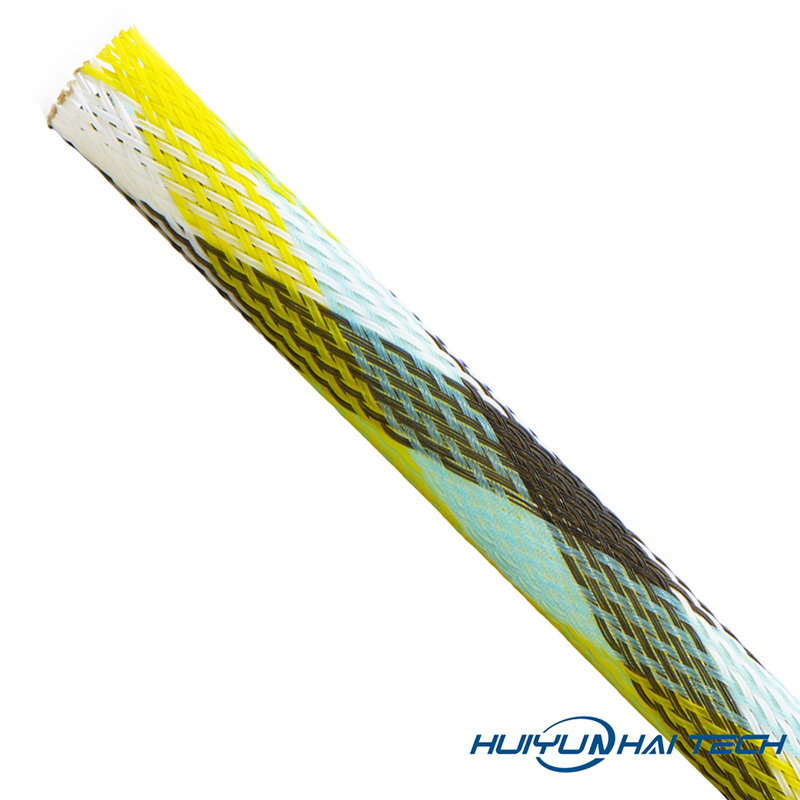

There will be many problems in the production process of Nylon Braided Sleeve, such as lack of material, flow marks, burrs and other problems. Today, the editor will tell you the reasons for the lack of material in Nylon Braided Sleeve and how to deal with them.

1. The reasons for the shortage of Nylon Braided Sleeve are as follows:

① The height of the cavity is different, the gap between the cavity is too large, and the exhaust condition of the mold is not good;

②Insufficient unit consumption of semi-finished products or insufficient glue loading;

③ Insufficient pressure;

④The fluidity of

Cable Sleeve is too poor;

⑤The mold temperature is too high, and the Cable Sleeve is scorched;

⑥Early scorch (dead material) of Cable Sleeve;

⑦ The material is not thick enough and the flow is not sufficient;

⑧The plate rises too fast, and the Cable Sleeve does not flow sufficiently;

⑨The mold temperature is too high;

⑩ improper use of release agent;

Second, the solution to the shortage of Nylon Braided Sleeve:

①Modify the mold to ensure proper fit and consistent height, and add exhaust slots to exhaust more;

②Adjust the unit consumption and the shape of the molded parts;

③ Increase the pressure;

④ Modify the formula to increase the fluidity of the braided mesh pipe;

⑤Change the formula to prolong the scorch time;

⑥Improve the storage conditions and time of braided mesh pipes;

⑦ Increase material thickness;

⑧Slow down the rising speed of the plate;

⑨Reduce mold temperature and speed up operation;

⑩Adjust the ratio and dosage of release agent.

3. How to deal with the lack of material when the hardness of the lower Nylon Braided Sleeve is high or low:

①The formula with low hardness generally has more oil. If it is parked for too long, the surface will inevitably ooze out, so it needs to be refined again. However, the fluidity will increase after refining, so it should be cooled and parked.

② For things with low hardness, if the material is injected quickly, it may cause insufficient back pressure of the Cable Sleeve and wrap air bubbles, so the speed of the Cable Sleeve entering the mold cavity should be reduced. Where possible, Cable Sleeve should be cold enough to reduce fluidity.

③You can add something similar to TT to the formula, or you can add a small amount of rubber powder.