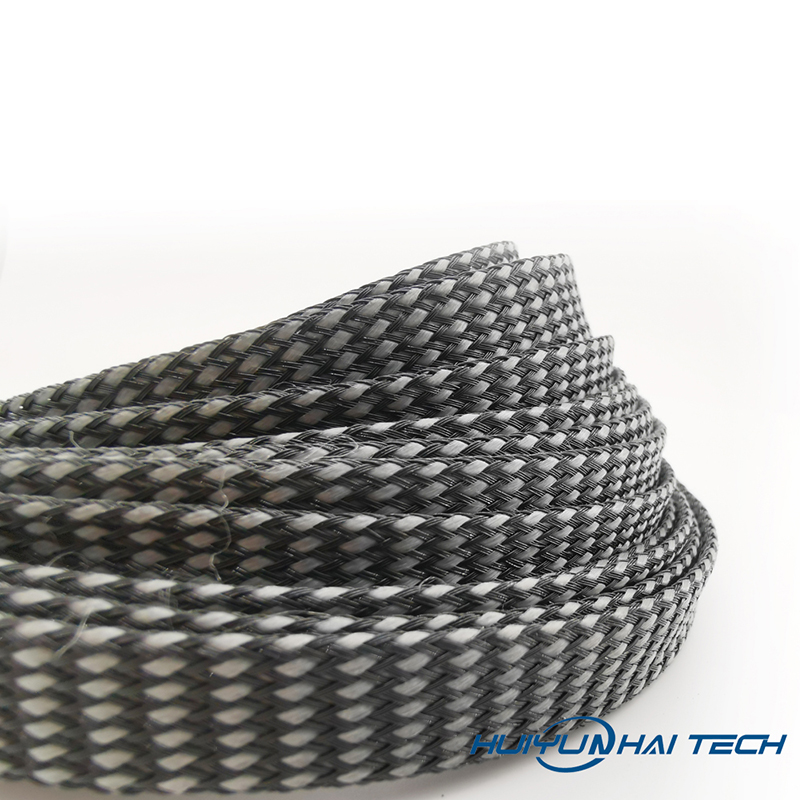

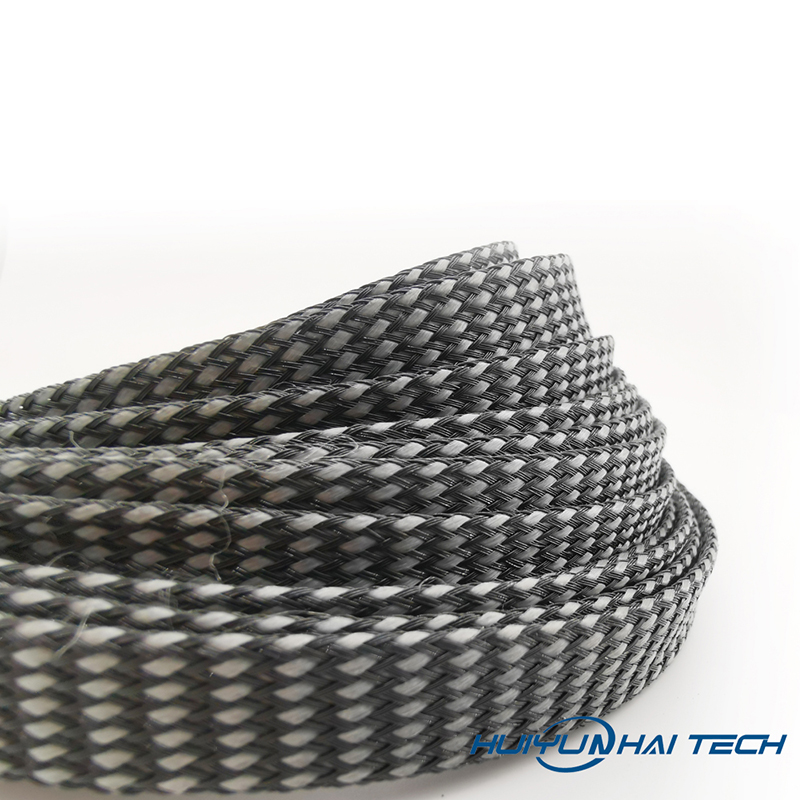

Many people don't know which one is better to choose between molded Pattern Braided Sleeve and extruded Pattern Braided Sleeve, so knowing their advantages and disadvantages is also very advantageous for us to choose products, so let's learn together with the editor today.

First of all, the raw material of Pattern Braided Sleeve is a rubber processing method that is formed by heating and pressing in a closed mold cavity. Generally, the powder sheet-shaped rubber block is first made into a blank with a shape similar to the product, placed in the cavity of a heated mold, and then the mold is closed and pressed to form and solidify or vulcanize, and then the product is demoulded, this method is especially suitable for the molding and processing of thermosetting products.

The advantages are: high precision, regular and beautiful product shape, so it can be made into any shape.

The disadvantages are: Generally, the length is less than 600 mm; and the production cycle is long and the efficiency is low; a lot of burrs and waste products will be generated in the production process; the cost of the mold is expensive, and the development cycle is relatively long.

Extrusion is generally based on the type of polymer to be processed and the shape of the product or semi-finished product, select the extruder, head and die, and the corresponding auxiliary devices such as shaping and traction, and then determine the extrusion process conditions such as screw speed , head pressure, material temperature, and shaping temperature, traction speed, etc. In the extrusion process, the material is generally plasticized, but the shaping method is different. For example, the extruded plastic often needs to be cooled and shaped to make it solidify, while the semi-finished product of extruded rubber needs to be further vulcanized.

The advantages are: it can be wirelessly long, the production cycle is fast, the production capacity is high, and there are few waste products; and compared with molding, the mold is cheap, and the development is convenient and fast.

The disadvantage is: the accuracy is poor, and some shapes are difficult to produce, so they can only be made into strips.

In short, whether it is extrusion or molding, each has its own advantages and disadvantages. When producing, manufacturers can choose a suitable production method according to their own needs.