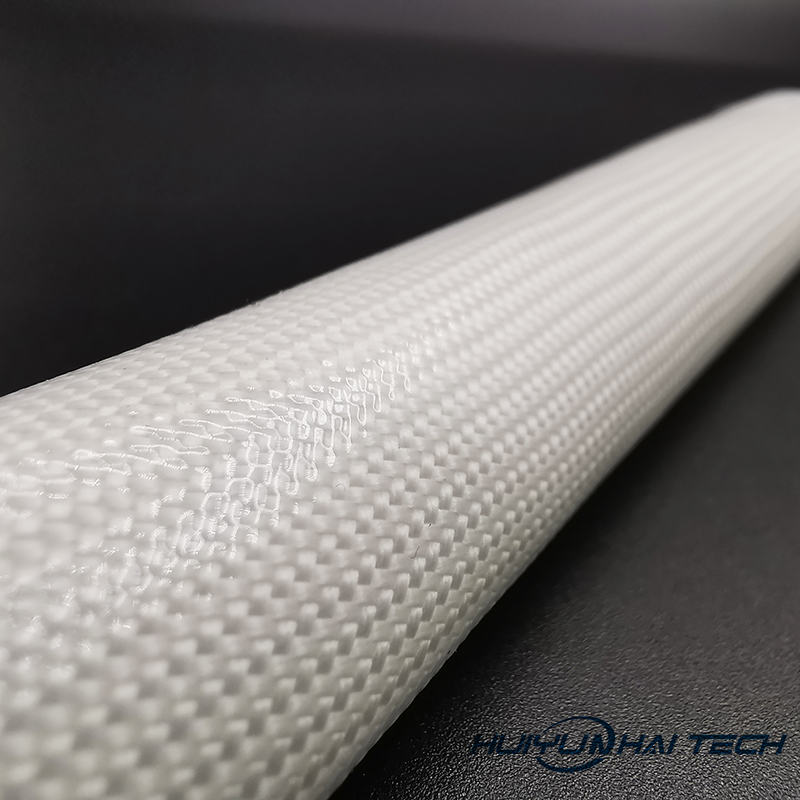

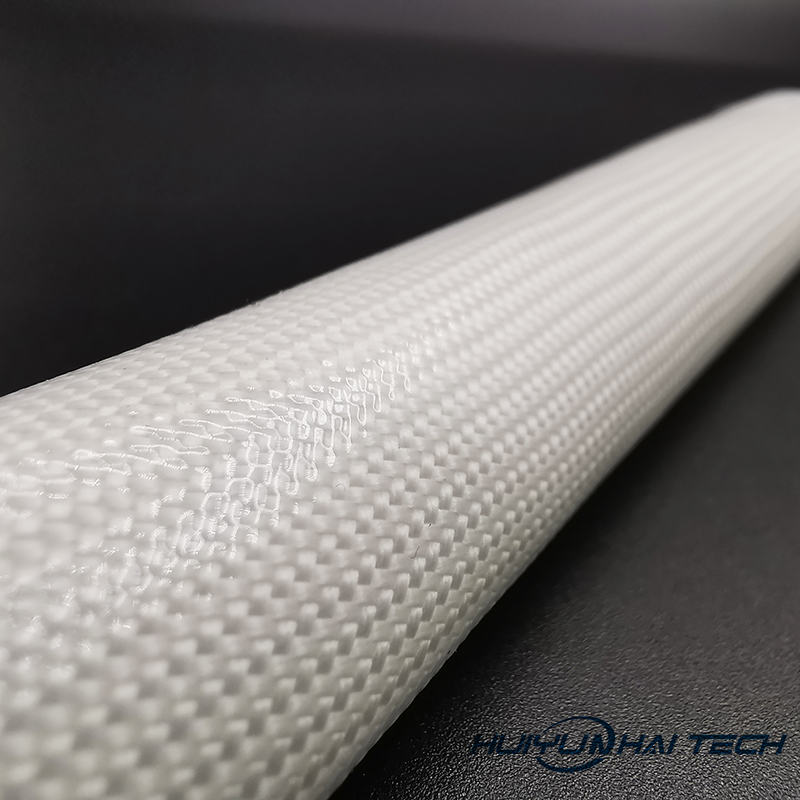

The formula of Polyester/Cotton Braided Sleeve is generally inconsistent in summer and winter due to the seasonal ambient temperature. To distinguish between the two, I usually adjust the amount of accelerator and Polyester/cotton Braided Sleeve, and the amount in summer is less than that in winter.

The main consideration is scorch, and the scorch time in summer should be longer to prevent the

Cable Sleeve during the rubber mixing process or the Cable Sleeve during storage. If the formula is properly matched, there is generally no problem. Our formula is not divided. We have encountered this situation now. The performance of the formula is very good in winter. In the past few days, the scorch time is short, and there is cooked glue when extruded, which is a headache to handle. If the formula is designed properly, it can be used regardless of season. If the formula blindly pursues fast Cable Sleeve to reduce costs, it will be easier for the above-mentioned problems to occur.

Due to limited conditions, we do not have a large enough air-conditioned room. When the order is large and the delivery time is short, the rubber compounded is more, and it is usually stored directly in the workshop without cooling measures, so it is easy to cause the scorching time of the rubber material. shorten. If there is no effective temperature-controlled storage warehouse, the formula must be adjusted in summer and winter. Otherwise, it goes without saying that the weather is scorching. I have added 0.5 parts of anti-scorch agent CTP, and the effect is not bad, but it is better to adjust the formula of the Cable Sleeve system. Reducing the amount of accelerators and Polyester/

Cotton Braided Sleeve to prolong the scorch time will definitely affect the physical properties of the formula, reduce the degree of crosslinking, reduce TB, and prolong T90, etc.

Because we have encountered a similar situation in the refining of nitrile rubber: the formula with good performance in winter, the scorch time becomes worse in summer

Short, extruded products have cooked rubber particles or tumors of different sizes, which affect the surface quality of the product and the comprehensive quality problem that can only be discovered after a delay. Therefore, it is adopted to reduce the amount of accelerators and Polyester/cotton

Braided Sleeve. Measures to prolong its scorch time, but also to ensure that the positive Cable Sleeve time changes are not very large, so as to ensure the stability and production efficiency of the extrusion process! Practice has proved that the effect is still good!