1. Description of the problem: The color of the Neoprene Velcro Cable Sleeve is uneven. The surface color of the same batch of Cable Sleeve is in contrast to the overall color, and the surface color of different batches of Cable Sleeve varies greatly.

Cause analysis: The color pollution of the equipment during the rubber mixing process of Neoprene Velcro Cable Sleeve is serious, the rubber material is unevenly toned, the vulcanization process is polluted, and the raw body is placed and stored.

solution:

① After the rubber type is switched, the rubber mixing machine must be cleaned, including accumulated rubber, dust and related pollutants.

②The process of heat refining and color matching must be carried out in strict accordance with the ratio and operation method required by the process documents.

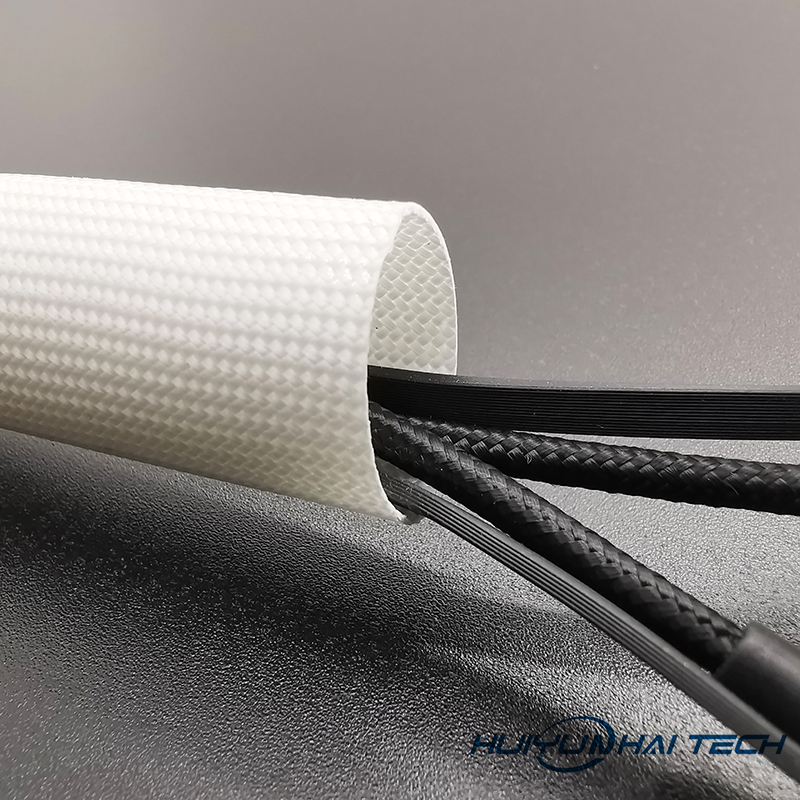

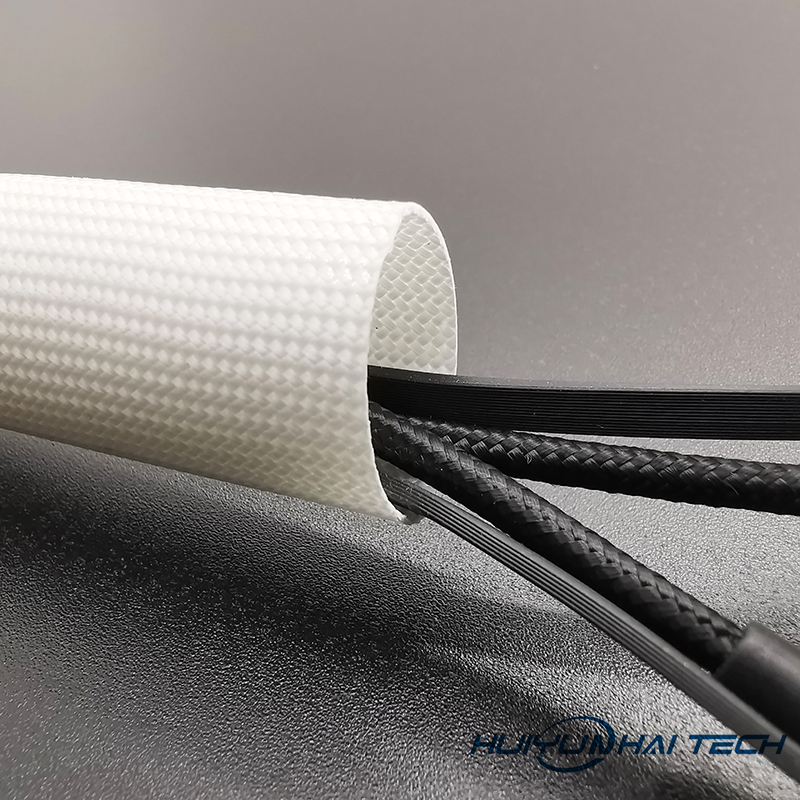

2. Description of the problem: the texture of the enhancement layer is uneven

Reason analysis: The Neoprene Velcro Cable Sleeve is mainly caused by the outer super-winding wire slipping due to hanging friction when the outer layer is covered with glue during the winding process, and the quality problems of the reinforced fiber wire: such as uneven thickness, inconsistent winding strength of the wire spindle, resulting in spindle failure. Looseness leads to poor adjustment of the tensioner during the production process and inconsistent tension.

①Strengthen the management and quality requirements of reinforcement material suppliers,

②The tension value of the tensioner must be checked before winding, and the setting of the tensioner during the winding process is strictly in accordance with the process requirements.

3. Description of the problem: spray frost

Reason analysis: inappropriate selection of materials for formula design, inappropriate dosage of materials for formula design, inappropriate control of temperature, time pressure, etc. in the rubber mixing process, resulting in problems in the uniformity of dispersion, and problems in the process control of the molding process.

①Strictly control the varieties, specifications, models and manufacturers of materials required for the formula of Neoprene Velcro Cable Sleeve.

② Strictly control the rubber mixing process parameters of Neoprene Velcro Cable Sleeve.

③ Neoprene Velcro Cable Sleeve heating process control, including temperature, thin pass times, etc.

④ The vulcanization process must strictly implement the requirements of the process regulations.