Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

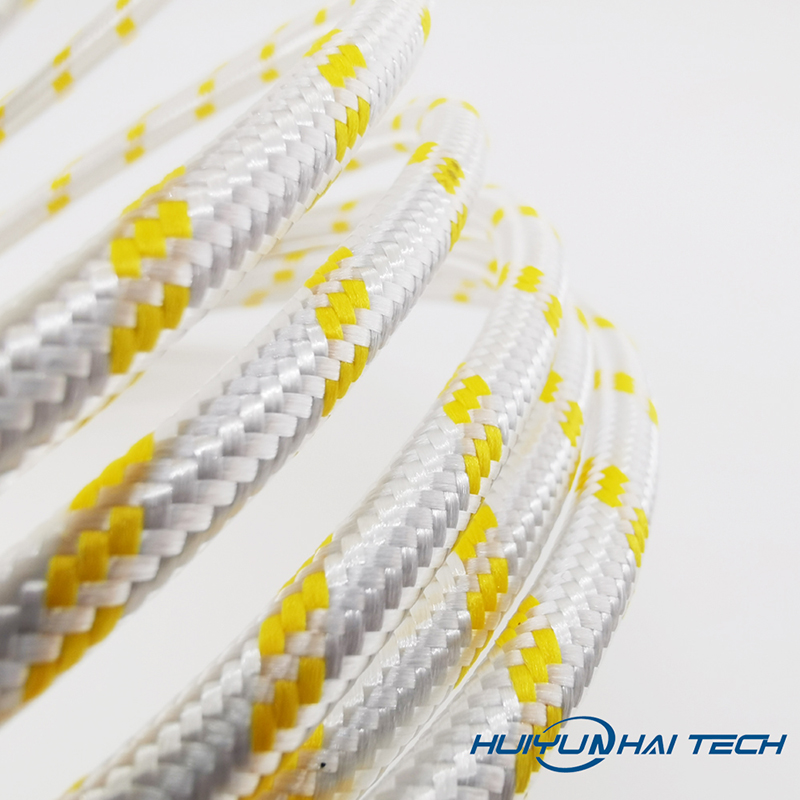

Kevlar Braided Sleeve are two-color extruded products in terms of production process. The products of the same period include neon silicone sleeves, two-color silicone straws, etc. These products require two silicone extruders to work together like Kevlar Braided Sleeve. The color, size and requirements of extruding machines are different, and the same is true for Kevlar Braided Sleeve. One extrusion equipment needs to extrude the transparent part of the transparent drainage tube body, while the other extruder needs to produce the blue developing part; The volume, size and shape of the developing line and the transparent tube body of the woven sleeve are different. Therefore, in terms of the production process, the two extruders need different extrusion speeds and molds, and then the two machines are fused into one machine. Head extruded Kevlar Braided Sleeve.

October 16, 2024

October 15, 2024

October 16, 2024

October 15, 2024

Email to this supplier

October 16, 2024

October 15, 2024

October 16, 2024

October 15, 2024

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.